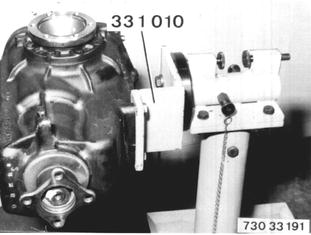

Vehicles after change point in 1982 REPLACING LIMITED SLIP DIFFERENTIAL ASSEMBLY - Final Drive Removed - Remove final drive - see 33 10 010 ind repair manual of pertinent model series beginning with 1985 models. Drain oil. Mount final drive on Special Tool 33 1 010. Installation: Add oil. Oil volume*. Refer to Service Information of Group 00 for approved oil.  33 10 010 33 10 010 * See Specifications * See Specifications

|  |

|

|

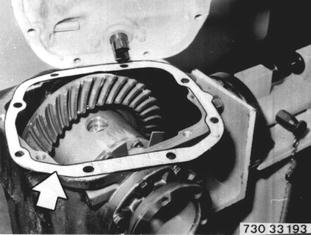

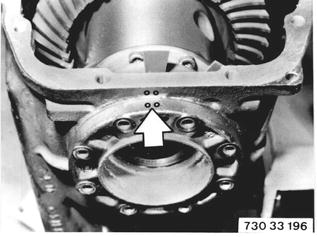

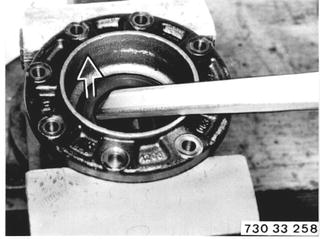

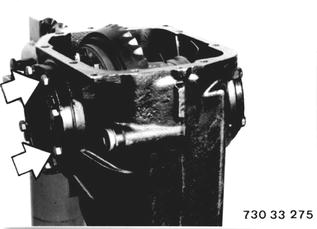

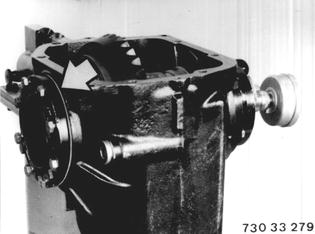

Pry off both drive flanges with a tire iron. |  |

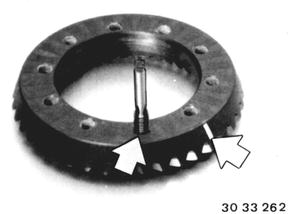

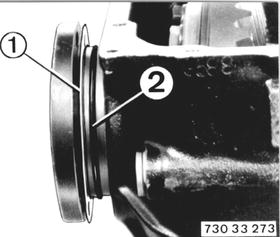

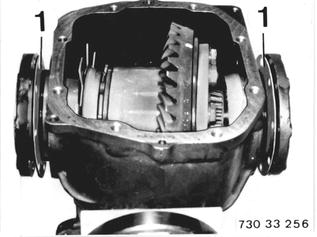

Installation: Before installation of the drive flange, place round wire snap ring (1) in groove of the differential case that both ends are recessed in groove. This prevents lateral bending of the ring. Push in and turn drive flange slightly by hand until round wire snap ring is heard to engage. Replace stretched snap rings. |  |

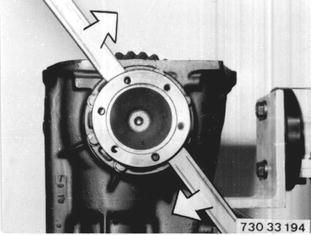

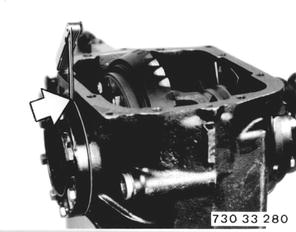

Unscrew both bearing caps. Important! Mark bearing caps and don´t mix them up. Installation: Tightening torque*.  * See Specifications * See Specifications

|  |

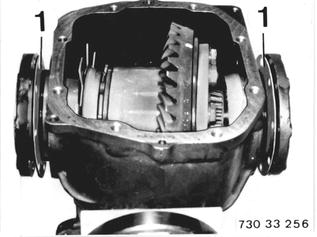

Differential case bearings and backlash are adjusted with shims (1). Check O-ring (2), replacing if necessary. Important! Changing the total thickness of shims (1) will change the friction torque value. After adjusting the friction torque, the backlash and tooth contact pattern will have to be adjusted again - see 33 12 551.  33 12 551 33 12 551

|  |

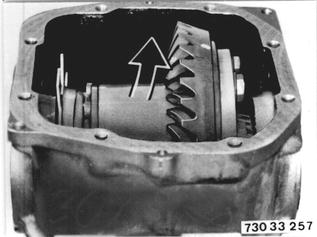

Remove complete limited slip differential. Installation: Don´t bend the pulse spider. |  |

Press off pulse spider. Installation: Press on pulse spider with Special Tool 33 1 304. |  |

Remove ring gear (cold). Installation: Clean threads thoroughly (with a tapper). Heat ring gear to max. 100°C (212°F), checking temperature with a thermocolor pencil. |  |

Important! If the drive pinion does not have to be removed, the friction torque can be measured prior to installation of the ring gear. Mount the ring gear with two locally made staybolts as guides. |  |

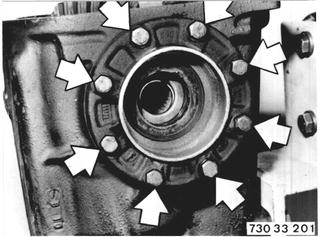

Install new bolts with Loctite No. 270 and tighten in order of (1 ... 10). Tightening torque*. Tighten bolts to torque angle*.  * See Specifications * See Specifications

|  |

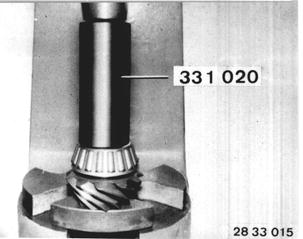

Press on new tapered roller bearing cold with Special Tool 33 1 330. |  |

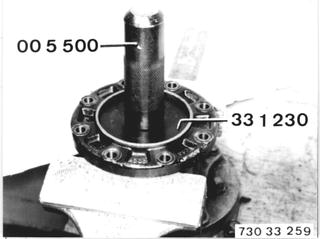

Lift shaft seals out of both bearing caps. |  |

Installation: Dip new shaft seals in final drive gear lube. Drive in shaft seals against stop with Special Tools 33 1 230 and 00 5 500. |  |

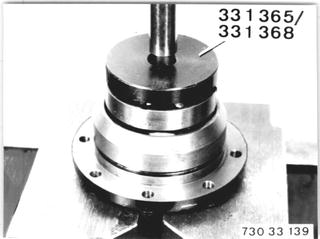

Press out bearing outer race with Special Tools 33 1 350 and 33 1 351. Important! Special Tool 33 1 351 must engage in bearing outer race. |  |

Installation: Press in new bearing outer races with Special Tool 33 1 365 or 33 1 368. |  |

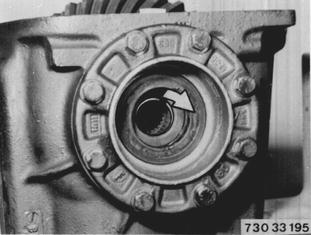

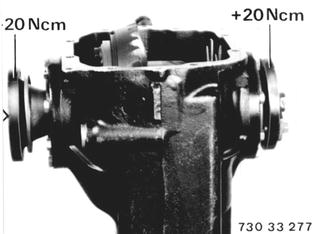

Removing and Installing Drive Pinion (If Applicable): Measure friction torque with Special Tool 00 2 000 and note value. Important! The measured friction torque + the friction torque of a new shaft seal (20 Ncm/2 in.lbs.) must be reached after assembling, but not exceeded. |  |

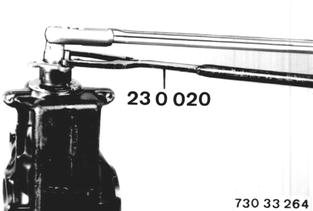

Hold input flange with Special Tool 23 0 020 and unscrew collar nut. Installation: Tightening torque*.  * See Specifications * See Specifications

|  |

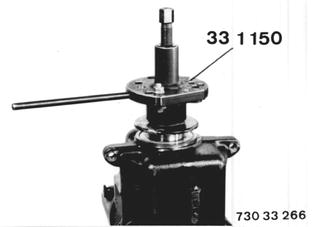

Pull off input flange with Special Tool 33 1 150. |  |

Pull out shaft seal with Special Tool 00 5 010 and a thrust piece. |  |

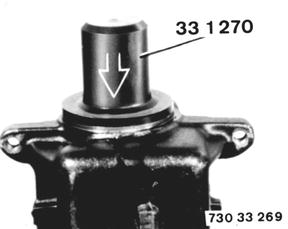

Dip new shaft seal in final drive gear lube** and drive it in flush with Special Tool 33 1 270 or 33 1 190.  ** See Service Information of Gr. 00 ** See Service Information of Gr. 00

|  |

Install new limited slip differential with pulse spider and new bearing. Lubricate bearing thoroughly with approved final drive gear lube** and allow to drip dry. Install marked side bearing covers with corresponding shims (1), but at first without O-rings (2). Tighten bearing cap bolts uniformly on end opposite the ring gear. Tightening torque*.  ** See Service Information of Gr. 00 ** See Service Information of Gr. 00 * See Specifications * See Specifications

|  |

Tighten the bolts of the second bearing cap uniformly enough, that the differential can still be turned easily. |  |

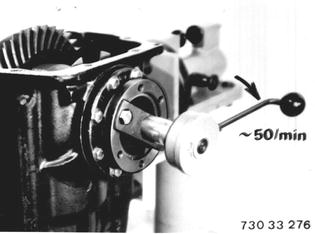

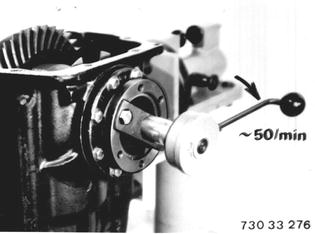

Install an output flange on the end tightend to tightening torque and measure the friction torque with a locally made clamp with welded nut and Special Tool 00 2 000. Turn friction torque meter at speed of 50 rpm. |  |

The friction torque given with the new differential bearing set +20 Ncm (2 in.lbs.) for each shaft seal, in which a shaft runs while measuring, must be reached, but not exceeded. |  |

If the given friction torque is not reached, even though both bearing caps are tightened to the correct tightening torque*, a thinner shim must be used on the end opposite the ring gear and the measuring procedures repeated.  * See Specifications * See Specifications

|  |

If the firction torque is reached, even though the second bearing cap is not yet tightened to correct tightening torque*, use a thicker shim on the ring gear end and repeat the measuring procedures.  * See Specifications * See Specifications

|  |

To make finding the thickness of shims easier, the distance between the shim and case can be measured with a feeler gage blade and this value is then added to the thickness of the used shims. |  |

Example: Second bearing cap not tightened (bolts screwed in uniformly). Friction torque specified in bearing set package = 180 Ncm (15 in.lbs.). One output flange mounted. New shaft seal = 20 Ncm (2 in.lbs.). Measured torque = 200 Ncm (17 in.lbs). Gap measured with feeler gage blade................... 0.20 mm (0.008´´) Used shim thickness.............. 1.40 mm (0.055´´) _____________________________________ Install shim with...................... 1.60 mm (0.063´´) thickness and repeat measurement. |  |

Remove differential for installation of drive pinion (or to install ring gear). Important! Don´t mix up side covers and shims. |  |

|

|

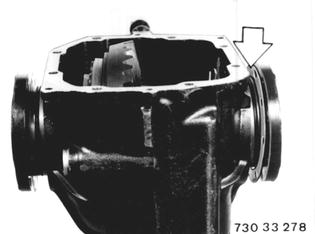

Install new limited slip differential with ring gear and pulse spider. Install marked side bearing caps with corresponding shims and new O-rings. Tighten bearing cap bolts uniformly. Tightening torque*.  * See Specifications * See Specifications

|  |

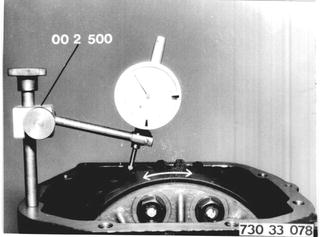

Mount Special Tool 00 2 500 and measure backlash* with the dial gage. Important! The tooth contact pattern is always most important for perfectly adjusted pinion/ring gear sets - see pages 33 - 111 - 112. |  |

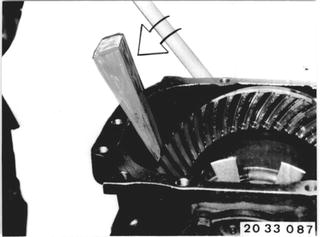

To check the tooth contact pattern, coat ring gear with printer´s ink, turn several times in both directions and then stop the ring gear suddenly with a piece of hard wood. The backlash* and tooth contact pattern are corrected by changing the thickness of both shims (1). If the backlash is too large, install a thinner shim on the ring gear end. If the backlash is too small, install a thicker shim on the ring gear end. An axial displacement of the ring gear by 0.01 mm (0.0004´´) will change the backlash by 0.076 mm (0.0003´´).  * See Specifications * See Specifications

|  |

Important! The total thickness of both shims may no longer be changed. If a thicker or thinner shim was required to correct the tooth contact pattern, the total thickness must be corrected with the second shim, since otherwise the friction torque of the bearings would be changed again. |  |

BMW 628csi - M635csi (M6)»33 - Rear axle»33 14 520 a - Limited slip differential assembly - replace (M6)