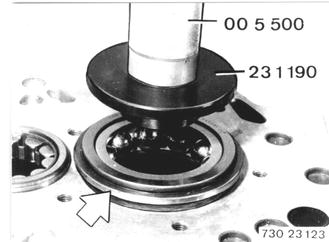

Vehicles after change point in 1982 REPLACING BEARINGS OF ALL TRANSMISSION SHAFTS - Transmission Removed - A) IInput Shaft, Layshaft in Case Front Section: Remove case front section 23 11 013. Drive ball bearing out of and into case with Special Tools 23 1 190 and 00 5 500. Important! Install ball bearing that collar faces out.  23 11 013 23 11 013

|  |

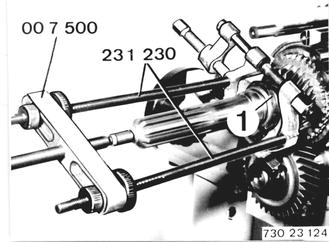

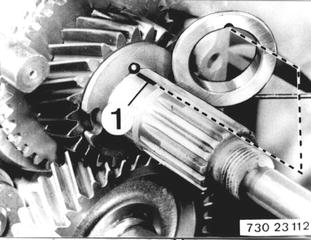

Pull bearing inner race (1) off of input shaft with Special Tools 23 1 230 and 00 7 500. |  |

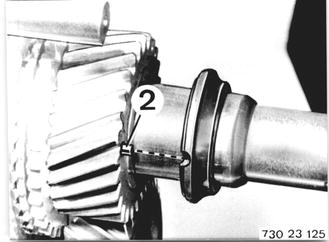

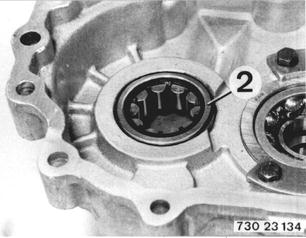

Installation: Heat bearing inner race to approx. 80°C (175°F) with a hot air blower and install on input shaft. Important! Turning lock. Pin (2) must be in opening of bearing inner race. |  |

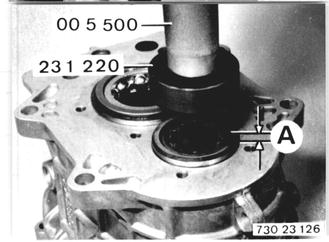

Drive layshaft roller bearing out and in with Special Tools 23 1 220 and 00 5 500. Protrusion A = approx. 5 mm (0.197´´). Install roller bearing that open end faces in. |  |

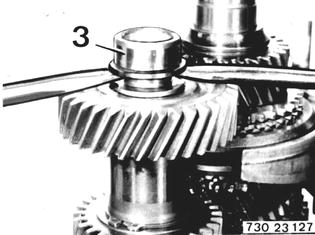

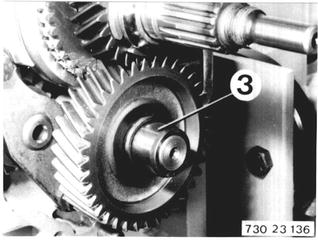

Press bearing inner race (3) off of layshaft with a screwdriver. |  |

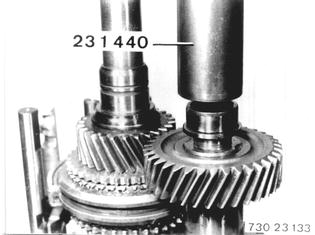

Installation: Heat bearing inner race to approx. 80°C (175°F) and install on layshaft, driving on to fit tight with Special Tool 23 1 440 if necessary. Collar of bearing inner race faces gear. |  |

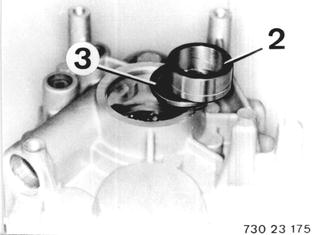

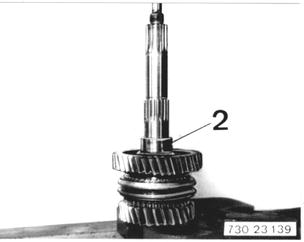

B) Output Shaft, Layshaft in Case Rear Section: Remove case rear section 23 11 022. Lift out radial oil seal. Remove spacer (2) and bearing inner race (3).  23 11 022 23 11 022

|  |

Unscrew bolts. Remove bearing holder. |  |

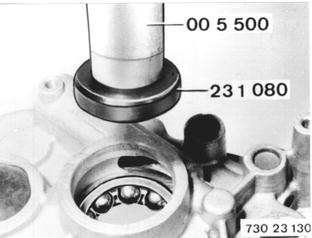

Drive out ball bearing with Special Tools 23 1 080 and 00 5 500. |  |

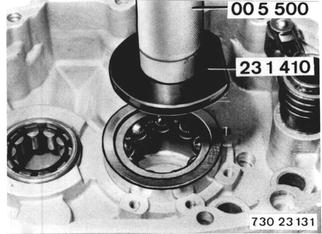

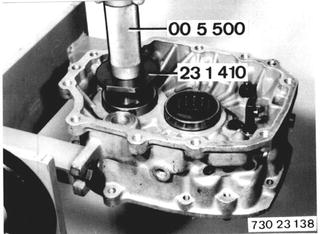

Drive in ball bearing with Special Tools 23 1 410 and 00 5 500. |  |

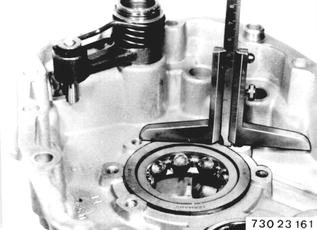

Adjust play between bearing holder and case rear section with shims. Mount bearing holder. Tightening torque*.  * See Specifications * See Specifications

|  |

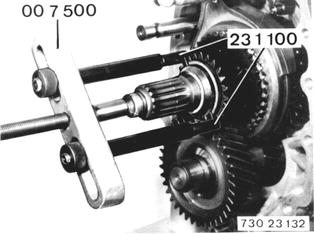

Pull ball bearing inner race off of output shaft with Special Tools 23 1 100 and 00 7 500. |  |

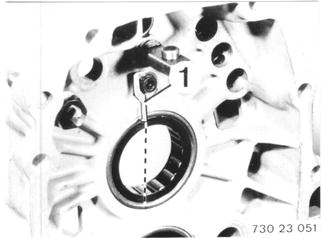

Installation: Heat ball bearing inner race to approx. 80°C (175°F) with a hot air blower and slide on to output shaft. Important! Opening in bearing inner race must engage in ball. Draw line (1) to make installation of bearing race easier. |  |

Heat case rear section to approx. 80°C (175°F) with a hot air blower. Lift out roller bearing (2). Installation: Insert bearing that large diameter end of plastic cage faces up. |  |

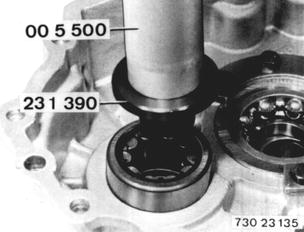

Heat case rear section to approx. 80°C (175°F) with a hot air blower. Install roller bearing, driving in with Special Tools 23 1 390 and 00 5 500. |  |

|

|

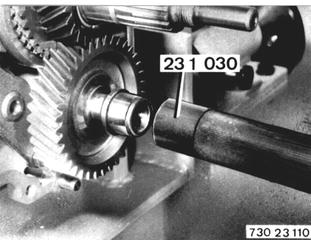

Heat new bearing inner race to approx. 80°C (175°F) with a hot air blower and install on layshaft, driving on with Special Tool 23 1 030 if necessary. Collar of bearing race faces gear. |  |

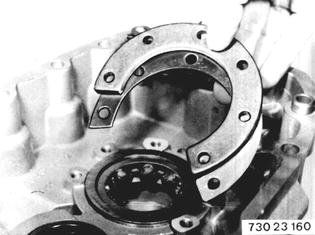

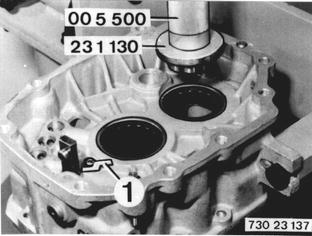

C) Output Shaft, Layshaft in Intermediate Case: Remove input and output shaft assembly 23 21 503. Drive roller bearings for input shaft and layshaft out of intermediate case with Special Tools 23 1 130 and 00 5 500. Important! Unscrew and turn oil plate (1) in case of roller bearing for output shaft.  23 21 503 23 21 503

|  |

Drive roller bearings for output shaft and layshaft into intermediate case with Special Tools 23 1 410 and 00 5 500. Drive in roller bearings flush. |  |

Bolt down oil plate (1) in vertical installed position. |  |

Check condition of bearing inner race (2) on output shaft, replacing if necessary. If replacement is necessary, press gear set off of output shaft (see 23 21 554).  23 21 554 23 21 554

|  |

BMW 628csi - M635csi (M6)»23 - Transmission-manual»23 21 703 a - Bearings for all transmission shafts - replace