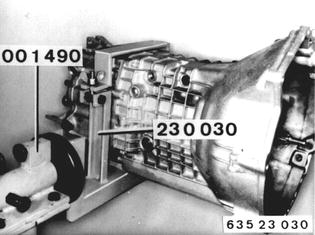

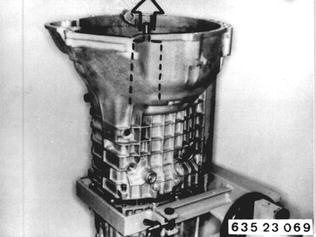

Vehicles after change point in 1982 REMOVING AND INSTALLING/SEALING FRONT AND REAR TRANSMISSION CASE SECTIONS Remove transmission - see 23 00 022. Mount Special Tool 23 0 030 on Special Tool 00 1 490. Unscrew filler bolt. Drain oil. Mount transmission on special tool plate. Important! Check grade of oil and volume of oil*.  23 00 022 23 00 022 * See Specifications * See Specifications

|  |

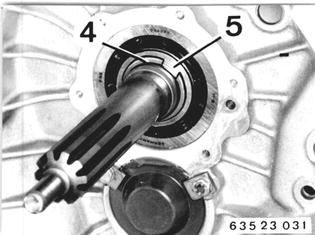

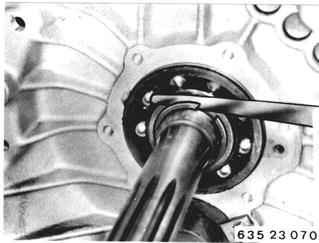

Remove guide sleeve - see 23 11 622. Lift out snap ring (4). Take off washer (5). Installation: Always replace the snap ring.  23 11 622 23 11 622

|  |

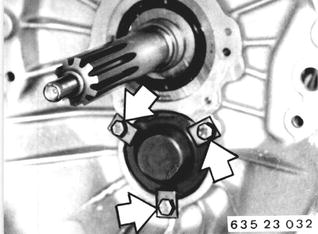

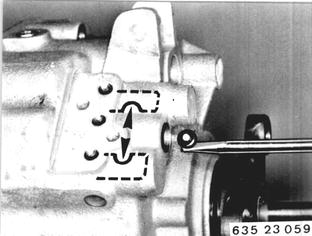

Unscrew mounting bolts for sealing cover. |  |

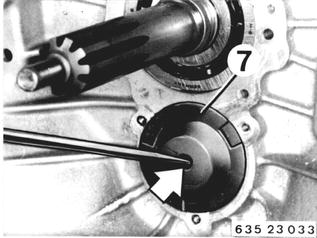

Punch through middle of sealing cover (7). Lift out sealing cover (7) with a screwdriver. Installation: Replace sealing cover. |  |

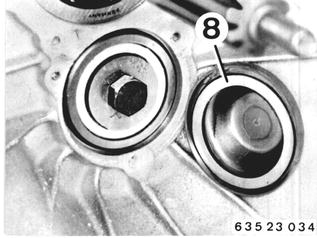

Take off sealing cover. Important! Spacer (8). |  |

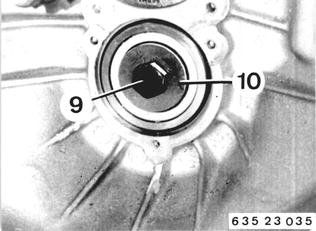

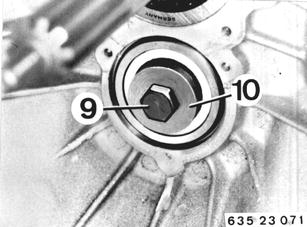

Engage 4th gear. Unscrew bolt (9) while holding the output flange with Special Tool 23 0 020. Take off washer (10). Installation: Install bolt (9) with a bolt cement. |  |

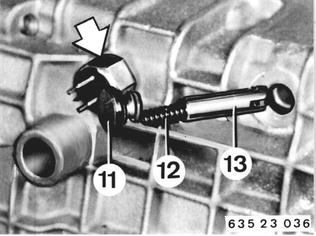

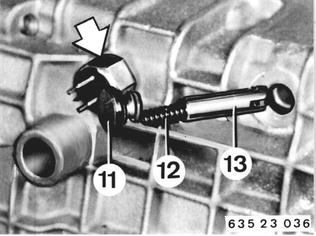

Unscrew backup light switch. Lift out cover (11). Pull out spring (12) and lockpin (13). Check installed position. |  |

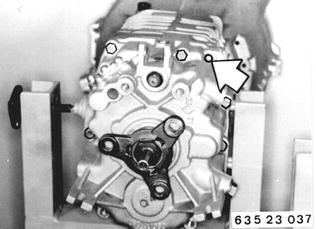

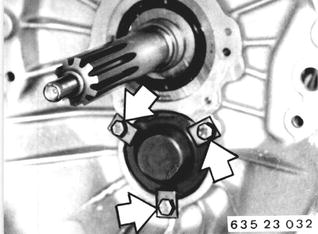

Knock back the cylindrical pins. Unscrew mounting bolts. |  |

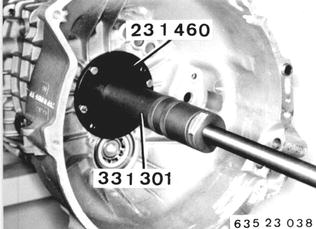

Pull off front case section with Special Tools 23 1 460 and 33 1 301. |  |

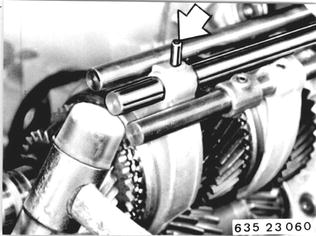

Fourth gear is engaged. Drive pin (14) out of selector shaft while counterholding. |  |

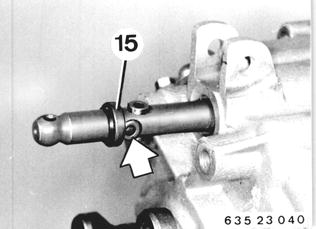

Drive out selector shaft toward the rear. Radial oil seal (15) will also be pulled out. Important! Grooves on selector shaft. Take off selector arm. Installation: Replace radial oil seal. |  |

Unscrew end cover. Installation: Install end cover with a surface sealing compound. |  |

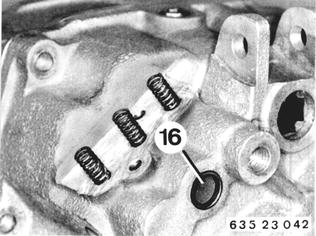

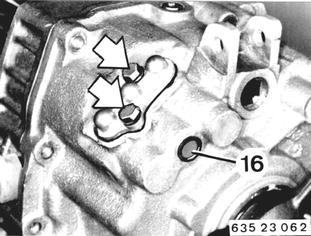

Remove three springs. Remove sealing sap (16). Installation: Replace sealing cap. |  |

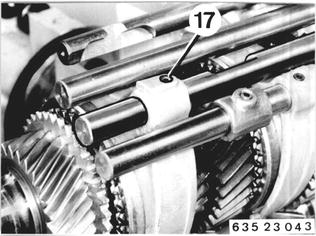

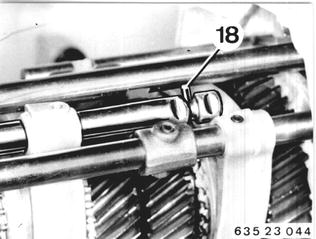

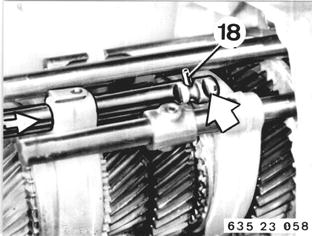

Take out 4th gear. Drive pin (18) out of 3rd/4th gear selector rod while counterholding. |  |

Knock out 3rd/4th gear selector rod forward. Important! Check lockpin (18). |  |

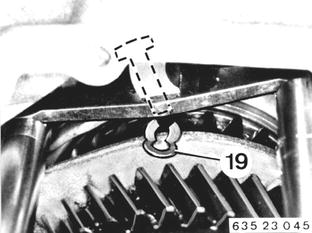

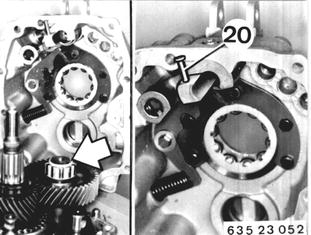

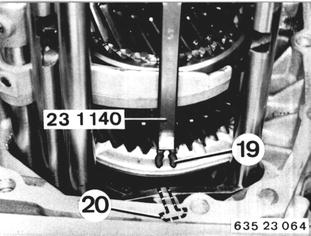

Pull retainer (19) off of bearing shaft for operating lever. |  |

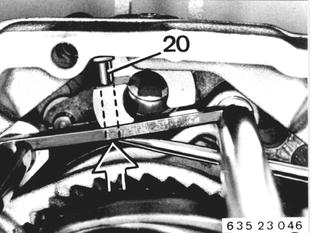

Push up bearing shaft (20). |  |

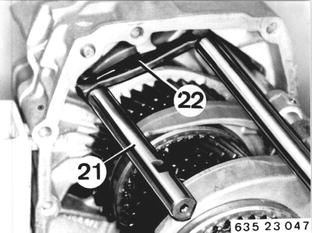

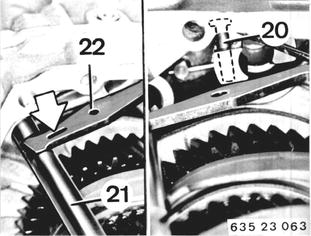

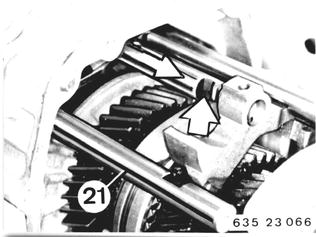

Pull out selector rail (21) forward. Take off operating lever (22). Installation: Mark on operating lever faces up. |  |

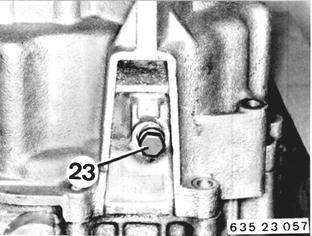

Unscrew bolt (23) for reverse gear shaft. Installation: Install bolt with a bolt cement. |  |

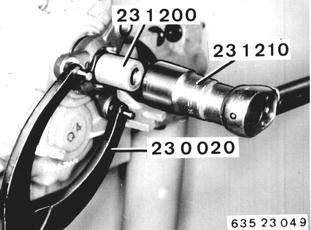

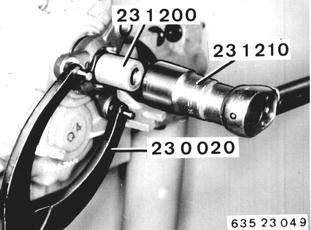

Lift out lockplate. Apply Special Tool 23 1 200. Hold output flange with Special Tool 23 0 020. Unscrew collar nut with Special Tool 23 1 210. |  |

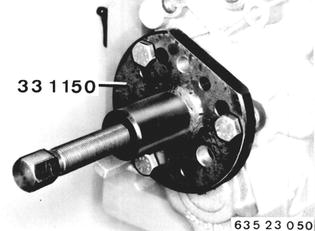

Pull off output flange with Special Tool 33 1 150. |  |

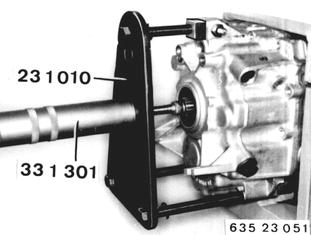

Knock back cylindrical pins. Pull off rear case section with Special Tools 23 1 010 and 33 1 301. |  |

Installation: Coat sealing surface with a surface sealing compound. Sealing surface must be absolutely clean and free of oil. Install roller bearing with the small diameter end of the plastic cage facing up. Important! Bearing shaft (20) for the operating lever must be installed and the bearing inner race removed prior to mounting the rear case section. This requires lifting out the radial oil seal. |  |

Mount the rear case section. Center 1st/2nd gear selector rod. Drive in cylindrical pins. |  |

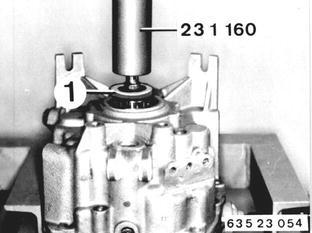

Heat bearing inner race (1) to about 80°C (175°F) with a hot air blower and slide it onto the output shaft, pressing on with Special Tool 23 1 160 if necessary. |  |

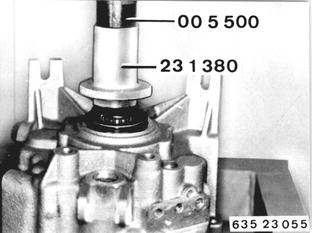

Drive in radial oil seal with Special Tools 23 1 380 and 00 5 500. Lubricate sealing lip with oil. |  |

Mount the output flange. Screw on collar nut with a bolt cement. Apply Special Tool 23 1 200. Hold output flange with Special Tool 23 0 020 and tighten the collar nut with Special Tool 23 1 210. Tightening torque*.  * See Specifications * See Specifications

|  |

Install lockplate. |  |

Install bolt (23) for the reverse gear shaft with a bolt cement and tighten to correct torque*.  * See Specifications * See Specifications

|  |

Slide 3rd/4th gear selector rot through the selector forks. Install lockpin (18) in selector rod with grease. Slide in selector rod up to the bore. Opening in selector rod faces up. |  |

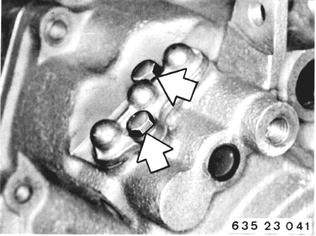

Insert two locking balls with grease. Slide in 3rd/4th gear selector rof up to the lock. |  |

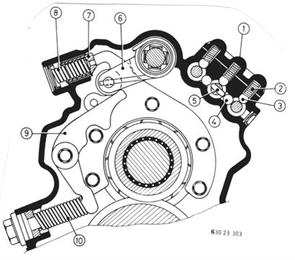

Arrest Layout: 1 Cap 2 Spring 3 Locking ball 4 Detent ball 5 Lockpin 6 Selector arm 7 Locking pin 8 Spring 9 Locking lever 10 Spring |  |

Drive 6 x 26 mm pin into the 3rd/4th gear selector fork while counterholding. |  |

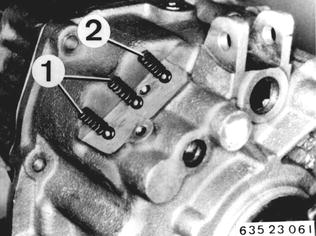

Install 3 locking balls and 3 springs. Important! Check length of springs. Relaxed length of springs (1) = 20.5 mm (0.807´´). Relaxed length of springs (2) = 15.9 mm (0.625´´). |  |

Coat cap with a surface sealing compound and tighten. Tightening torque*. Install sealing cap (16) with a surface sealing compound.  * See Specifications * See Specifications

|  |

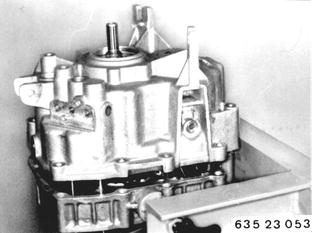

Install selector rail (21). Push up bearing shaft (20) and install operating lever (22) with mark facing up and toward the selector rail. |  |

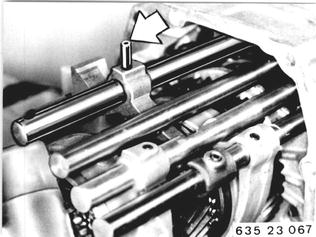

Position drive shaft vertically. Slide bearing shaft (20) in direction of the gear wheel set. Install retainer (19) with Special Tool 23 1 310. |  |

Hold 4 rollers in position with grease. |  |

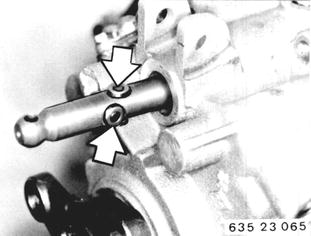

Insert selector arm. Slide in the selector shaft. Important! The opening in the selector shaft faces selector rail (21). |  |

Drive in 6 x 26 mm pin while counterholding. |  |

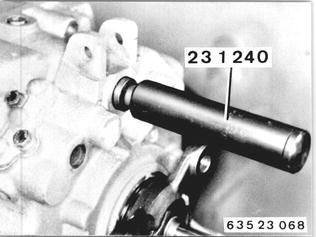

Lubricate sealing lip of radial oil seal with oil. Drive in radial oil seal with Special Tool 23 1 240. |  |

Coat sealing surface with a surface sealing compound. The sealing surface must be absolutely clean and free of oil. Heat bearing inner race of input shaft to about 80°C (175°F) with a hot air blower. Mount the front case section, while pulling out the input shaft. Tighten front case section to correct torque*.  * See Specifications * See Specifications

|  |

Install spacer and circlip. Reduce any play between the bearing inner race and circlip to 0 ... 0.09 mm (0 to 0.0035´´). |  |

Engage 4th gear. Install washer (10) and bolt (9). Install bolt with a bolt cement. Tighten bolt (9) to correct torque* while holding the output flange with Special Tool 23 0 020.  * See Specifications * See Specifications

|  |

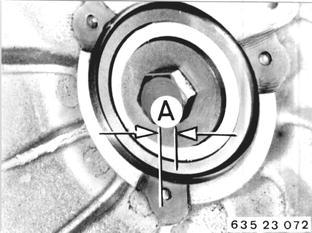

Determine thickness of shim (8) between the bearing outer race, layshaft and sealing cover. Measure distance (A) from the bearing outer race to the case opening for the mounting tabs. |  |

Measure wall thickness (B) of the sealing cover. Measure at the opening for the mounting tab. Example: ..A = 1.4 mm (0.055´´) - B = 0.9 mm (0.035´´) _________________ ........0.5 mm (0.020´´) shim thickness |  |

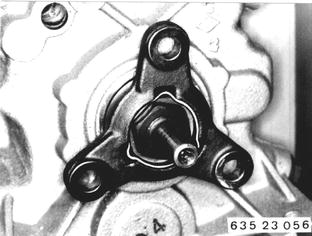

Hold shim of determined thickness in position with grease. Drive in sealing cover (7) with Special Tool 33 4 020 to fit tight. Important! Install sealing cover in such a manner, that wells in sealing cover are aligned with openings in case. |  |

|

|

Install locking pin (13), spring (12) and cover (11). Check installed position of locking pin. |  |

BMW 628csi - M635csi (M6)»23 - Transmission-manual»23 11 006 - Transmission case front and rear sections - remove and install/seal