Vehicles after change point in 1982 REPLACING SHAFT SEAL FOR FINAL DRIVE INPUT FLANGE Remove final drive - see 33 10 010. Mount final drive on Special Tool 33 1 010. Drain oil. Take off case cover. Installation: Replace gasket. Tightening torque*. Add oil. Oil volume*. See Service Information of Group 00 for approved oil.  33 10 010 33 10 010 * See Specifications * See Specifications

|  |

Remove lockplate. |  |

Press off drive flanges with a tire iron. |  |

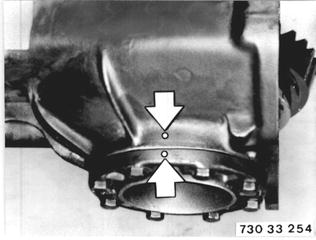

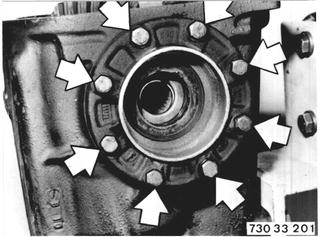

Punch mark both bearing caps. Remove both bearing caps. Important! Don´t mix up bearing caps and spacers. If necessary, tie spacers on bearing caps with pieces of wire. Installation: Tightening torque*.  * See Specifications * See Specifications

|  |

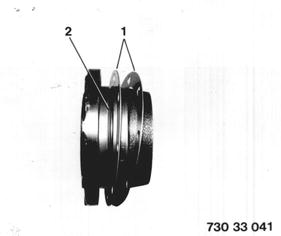

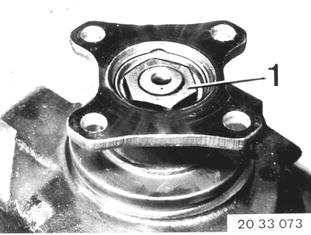

Differential case bearings and backlash are adjusted with shims (1). Check O-ring (2), replacing if necessary. |  |

Remove differential assembly. Important! Don´t bend pulse spider! |  |

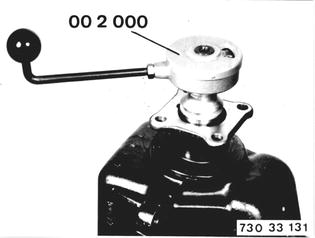

Measure friction torque with torque meter 00 2 000 and note value. Important! The measured frictiion torque value + friction torque of new shaft seal (20 Ncm/1.7 in.lbs.) must be reached when assemblind, but not exceeded. |  |

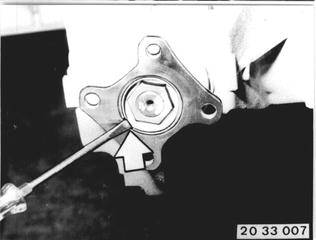

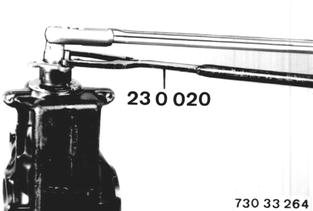

Hold input flange with Special Tool 23 0 020 and unscrew collar nut. Installation! Tightening torque*.  * See Specifications * See Specifications

|  |

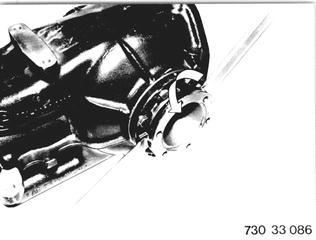

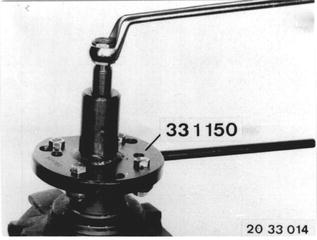

Pull off input flange with Special Tool 33 1 150. |  |

Pull out shaft seal with Special Tool 00 5 010 and thrust piece. |  |

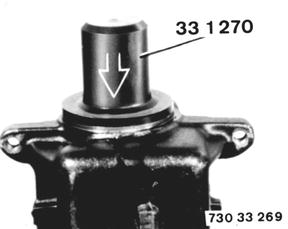

Dip shaft seal in final drive gear lube and drive in seal flush with Special Tool 33 1 270 or 33 1 190. |  |

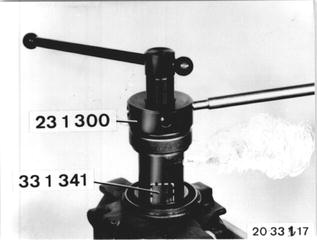

Press new input flange on to input shaft with Special Tool 23 1 300, and adapter 33 1 341, od not tighten. The bushing does not have to be replaced when replacing the input flange. |  |

Tighten input flange with the collar nut in steps, measuring the friction torque between steps. |  |

Adjust drive pinion bearing to friction torque value measured prior to disassembling and add 20 Ncm (2 in.lbs.) for new shaft seal. Example: Measured torque................. 160 Ncm (14 in.lbs.) New shaft sea...................l + 20 Ncm (2 in.lbs.) _____________________________________ Pinion bearing adjusted to... 180 Ncm (16 in.lbs.) |  |

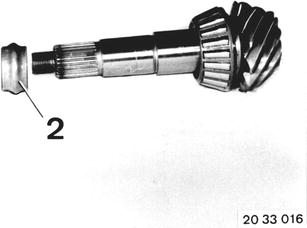

If fircition torque value (see example) is exceeded, replace bushing (2) and repeat measuring procedures. This requires removing and installing drive pinion - see 33 12 551. Installation: Drive in new lockplate with Special Tools 33 4 050 and 00 5 500.  33 12 551 33 12 551

|  |

Installation: Install complete differential again, checking for correct installation of bearing caps. Tighten bearing caps uniformly. If applicable, check backlash and tooth contact pattern. See 33 12 551 for additional information.  33 12 551 33 12 551

|  |

BMW 628csi - M635csi (M6)»33 - Rear axle»33 11 011 a - Shaft seal and input flange of final drive - replace (M6)