Vehicles after change point in 1982 REMOVING AND INSTALLING INPUT AND OUTPUT SHAFT ASSEMBLY - Front and Rear Transmission Case Sections Removed - Swing down output shaft. Pull 5th gear wheel off of layshaft with Special Tool 23 0 080. This also pulls off the bearing inner race. Pressing-off force*. Caution! Prevent pulling off tool from falling down.  * See Specifications * See Specifications

|  |

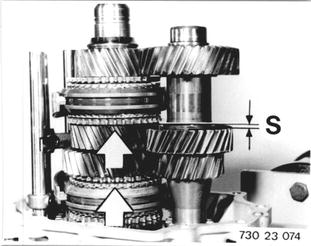

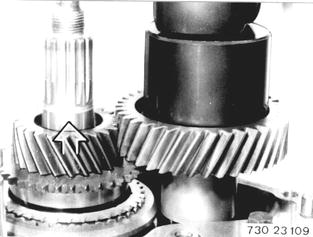

Important! When installing 5th gear always remember to provide play (S) between 3rd gear and layshaft, to avoid damaging the 3rd gear wheel. Push up output shaft if necessary. |  |

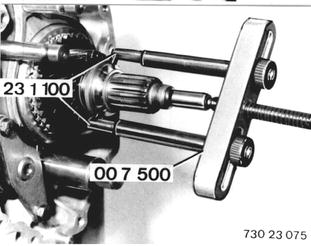

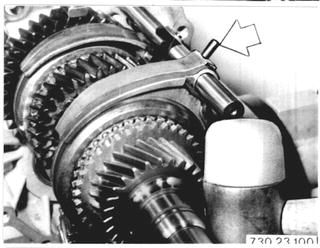

Pull bearing inner race off of output shaft with Special Tools 23 1 100 and 00 7 500. |  |

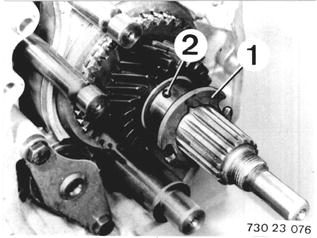

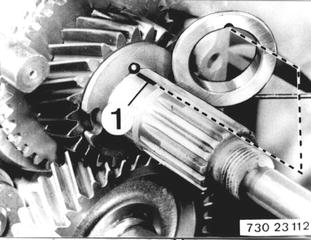

Take off washer (1) and ball (2). |  |

Pull off 5th gear wheel with synchromesh ring and split needle bearing. |  |

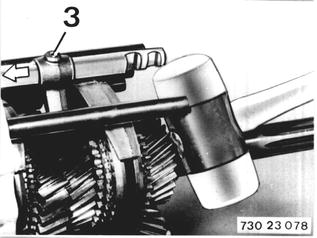

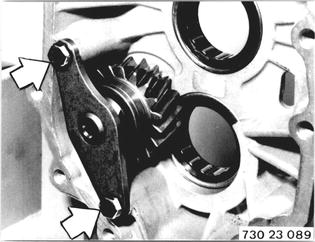

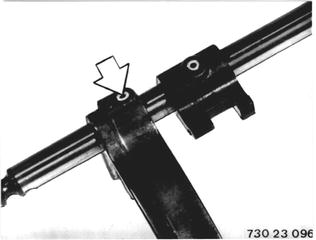

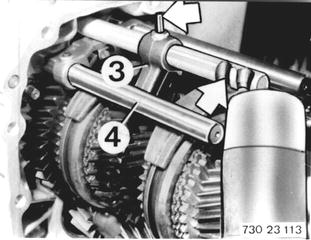

Remove needles on selector shaft. Drive out pin (3) in selector shaft, while counterholding. Pull out selector shaft toward rear. Remove selector arm. Installation: Replace pin. |  |

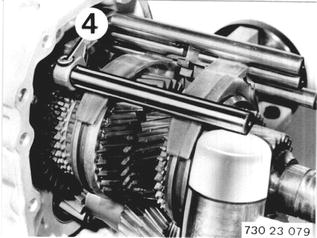

Engage 2nd gear. Drive out pin (4), while counterholding. Installation: Replace pin. |  |

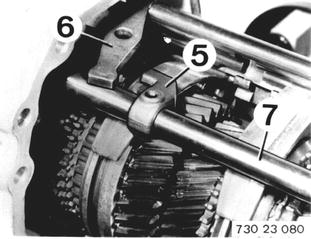

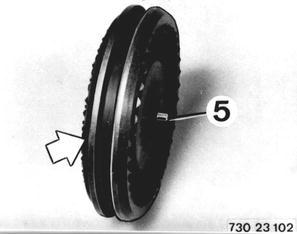

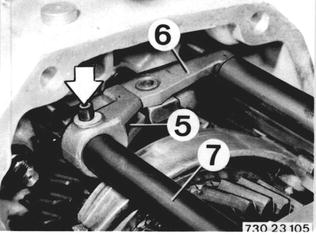

Pull or take off turning lock (5) and reversing lever (6). Pull out selector rail (7) forward. Disengage second gear. |  |

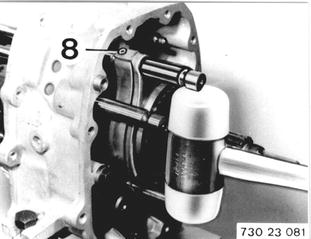

Pull out 5th gear selector rod with selector fork and operating sleeve toward rear far enough, that pin (8) can be driven out while counterholding. Important! Loose balls, springs and slides. Installation: Replace pin. |  |

Pull off operating sleeve and fifth gear selector fork. Pull out selector rod (9) forward. Important! Loose balls. |  |

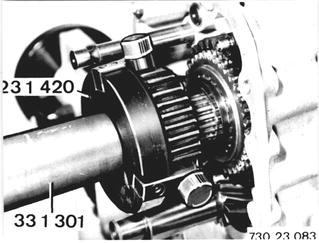

Pull guide sleeve and bearing inner race off of output shaft with Special Tools 23 1 420 and 33 1 301. Important! Hold knurled head bolts in recesses of guide sleeve with a pliers. |  |

Pull off reverse gear and needle bearing. |  |

Engage third gear. Drive out pin (10). Important! Drive in pin on to tooth of 3rd gear wheel until selector rod can be pulled out forward. Remove 3rd/4th gear selector fork. Loose balls. Installation: Replace pin. |  |

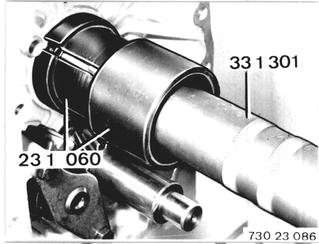

Pull out output shaft toward rear far enough, that bearing inner race can be pulled off with Special Tools 23 1 060 and 33 1 301. |  |

|

|

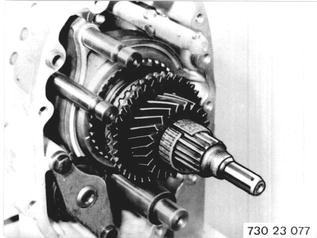

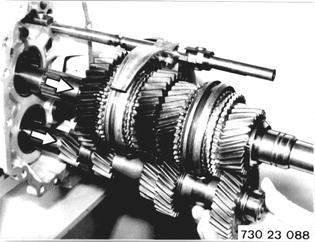

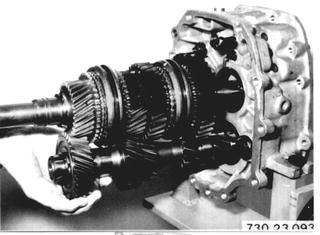

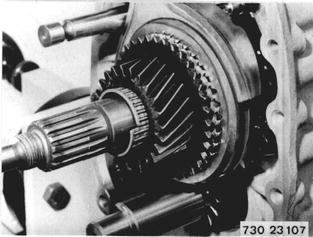

Pull out input and output shaft assembly with layshaft and 1st/2nd gear selector rod in intermediate case. Important! Loose balls. |  |

Deatch holder. |  |

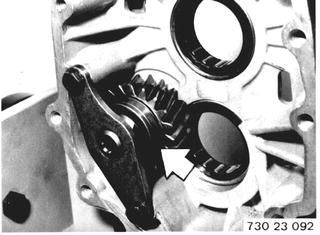

Unscrew bolt (11), while counterholding on front of shaft. Installation: Install bolt with Loctite No. 270. Tightening torque*. Remove washer (12).  * See Specifications * See Specifications

|  |

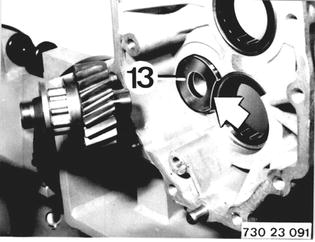

Knock out reverse gear shaft. Installation: Check installed position of thrust washer (13). Check needle bearing, replacind if necessary. Check condition of all bearings, replacing if necessary (see 23 21 703).  23 21 703 23 21 703

|  |

Installation: Install and mount reverse gear. Stepped collar of reverse gear faces out. Tightening torque*.  * See Specifications * See Specifications

|  |

Install input shaft, output shaft anf layshaft in intermediate case. |  |

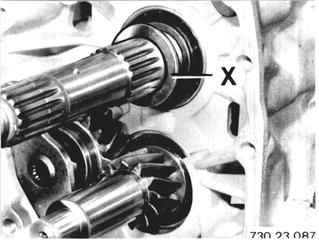

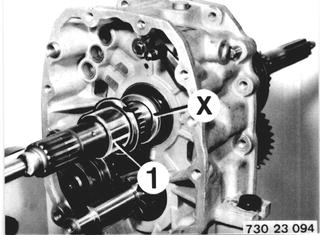

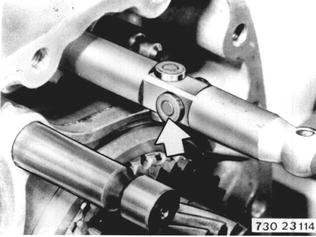

Install shim X. Heat bearing sleeve (1) to approx. 80°C (175°F) and install on output shaft. Heat with a hot air blower. |  |

Install needle bearing anf reverse gear. Push on synchromesh ring. |  |

Drive pin out of 1st/2nd gear selector rod. Installation: Replace pin. |  |

Mount 1st/2nd gear selector fork. Push in 1st/2nd gear selector rod up to spring. Insert locking balls and press down. Push in selector rod against arrest in this position. |  |

Drive in 6 x 32 mm pin, while counterholding. |  |

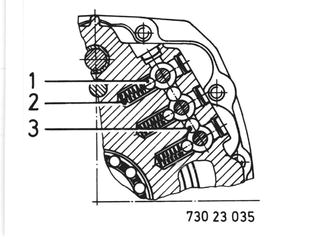

Layout of Selector Arrest: 1 Locking ball 2 Spring 3 Detent ball |  |

Mount 3rd/4th gear selector fork. Insert detent ball. Push in selector rod up to spring. Insert locking balls and press down. Push in selector rod against arrest in this position. |  |

Drive in 6 x 26 mm pin, while counterholding. |  |

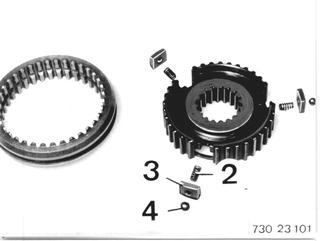

Assemble synchronizer. Installed Order: Springs (2), thrust parts (3) and balls (4). Curved surface of thrust parts (3) faces operating sleeve. |  |

Important! Stepped end of sliding sleeve be opposite centering pin (5). |  |

Install guide sleeve. Centering pin (5) faces 5th gear. Install 5th/reverse gear selector fork. Install detent ball. Push in selector rod up to spring. Insert locking balls and press down. Push in and turn selector rod that openings (1 and 2) are always opposite locking balls. |  |

Push in selector rod far enough that 6 x 26 mm pin can be driven in, while counterholding. Push in selector rod and guide sleeve against arrest. |  |

Install reversing lever (6). Smooth side faces down. Insert selector rail (7). Push on turning lock (5). Lock with 6 x 26 mm pin. |  |

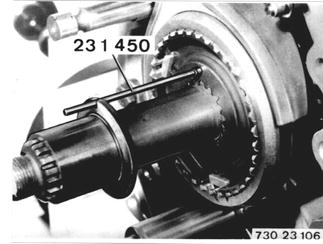

Place Special Tool 23 1 450 in centering pin. Heat bearing sleeve to approx. 80°C (175°F) with a hot air blower and push on to output shaft. |  |

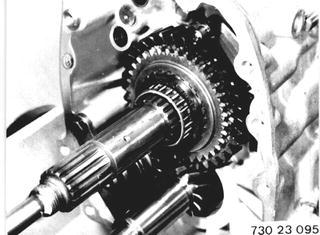

Install split needle bearing, synchromesh ring and fifth gear. |  |

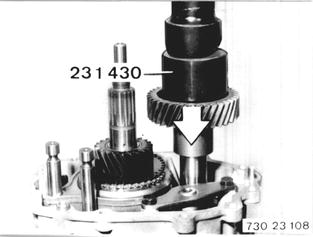

Detach intermediate case on mounting bracket and set up on a press. Lubricate pressing surface of layshaft with oil. Heat 5th gear uniformly to correct temperature* with a hot air blower. Press on 5th gear to fit tight with Special Tool 23 1 430. Pressing on force*.  * See Specifications * See Specifications

|  |

Important! Lift and turn 5th gear until teeth mesh. |  |

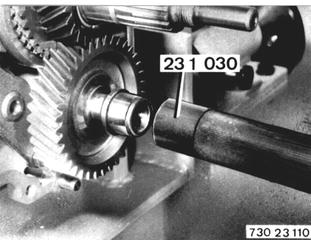

Heat bearing inner race to approx. 80°C (175°F) with a hot air blower and install on layshaft. If necessary, drive on with Special Tool 23 1 030. Collar of bearing race faces gear. |  |

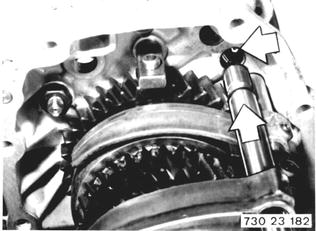

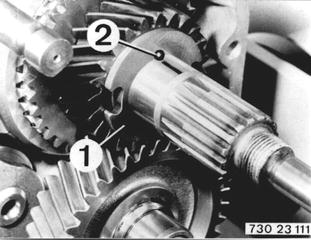

Insert ball (2) with grease. Push on washer (1). |  |

Installation: Heat ball bearing inner races to approx. 80°C (175°F) with a hot air blower and install on output shaft. Important! Turning lock. Opening in bearing inner race must engage in ball. Draw line (1) to make installation of bearing race easier. |  |

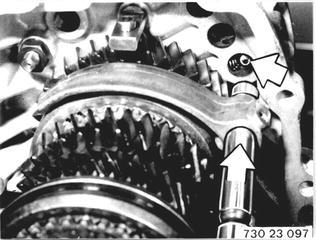

Install selector shaft, while pushing on selector arm (3) with long finger facing 3rd/4th gear selector rod. Important! Arrest on selector shaft faces selector rail (4). Drive in 6 x 32 mm pin, while counterholding. |  |

Hold four rollers in position on selector shaft with grease. |  |

BMW 628csi - M635csi (M6)»23 - Transmission-manual»23 21 503 a - Input and output shaft assembly - remove and install