Vehicles before change point in 1982 SERVICE INSTALLING LIMITED SLIP DIFFERENTIAL Take off ring gear (cold). Installation: Clean threads thoroughly (tap). Heat ring gear to max. 100°C (212°F), checking temperature with a thermocolor pencil. Install new bolts with Loctite No. 270 and tighten in order of 1 through 10. Tightening torque¹).  ¹) See Specifications ¹) See Specifications

|  |

Pull off taper roller bearings through openings in differential case with a standard puller and Special Tool 33 1 305. Installation: Press on taper roller bearings cold. Replace defective taper roller bearings. Further procedures are identical with those for "Replacing Locking Differential" - 33 14 011.  33 14 011 33 14 011

|  |

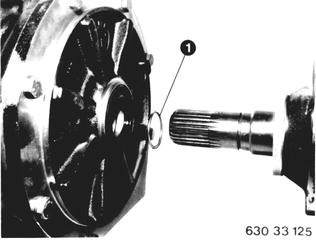

Remove wire snap ring (1) from differential case. Installation: Prior to installation of drive flange, place wire snap ring (1) in groove of differential case that both of its ends are recessed in groove. This will prevent lateral bending of snap ring. Press in drive flange by hand and turn slightly, until snap ring can be heard to engage. Replace stretched wire snap rings. |  |