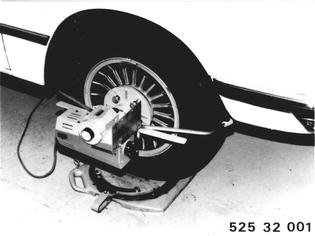

Vehicles before change point in 1982 CHECKING FRONT WHEEL ALIGNMENT OPTICALLY Accurate axle alignment requires fulfillment of the following points. 1. Good uniform tire treads. 2. Specified tire pressures. 3. Wheel rims in good condition. 4. Specified wheel bearing play. 5. Car brought to normal load condition¹). Determine actual values with optical equipment. Fill in test sheet. Specified values¹).  ¹) See Specifications ¹) See Specifications

|  |

20° right lock measured on left wheel 20° left lock measured on right wheel |  |

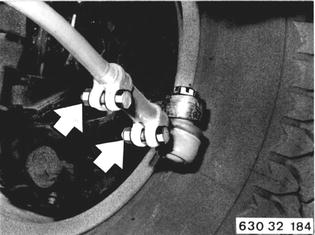

Adjusting Toe and Toe Difference Angle: Unscrew left and right bolts. |  |

Adjust steering gear to straight ahead position. Adjust toe to same value¹) on left and right wheels.  ¹) See Specifications ¹) See Specifications

|  |

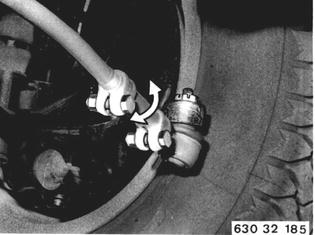

Installation: Tighten bolts to specified torque value¹`), making sure that the socket joints are not turned.  ¹) See Specifications ¹) See Specifications

|  |

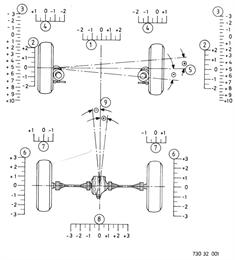

Vehicles after change point in 1982 CHECKING AND ADJUSTING ALIGNMENT OF FRONT WHEELS AND REAR WHEELS WITH OPTICAL TESTER Requirements prior to checking wheel alignment: 1. Good, uniform tire treads 2. Specified tire inflation pressure** 3. Wheel rims in perfect condition* 4. Specified wheel bearing play* 5. Car brought to normal position* 6. Specified height level* Check actual values with an optical tester. Fill in test sheet. Nominal values*.  * See Specifications of Gr. 31/32/33/36 * See Specifications of Gr. 31/32/33/36 ** See Service Information of Gr. 36 ** See Service Information of Gr. 36

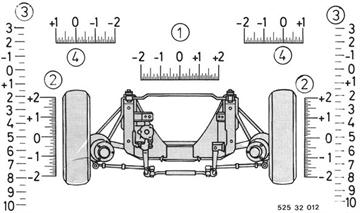

| |

WHEEL ALIGMENT @@K 1 = Toe 2 = Camber 3 = Caster (with 10° or 20° wheel lock) 4 = Toe difference angle (with 20° wheel lock) 5 = Wheel offset 6 = Camber 7 = Rear wheel position 8 = Toe 9 = Geometrical axis |  |

BMW 628csi - M635csi (M6)»32 - Steering and wheel alignment»32 00 034 - Front wheel alignment - checking