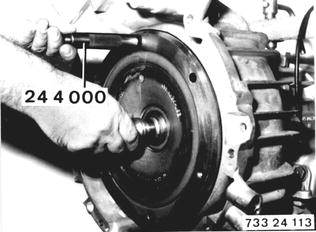

Vehicles after change point in 1982 REMOVING AND INSTALLING TORQUE CONVERTER Remove and install transmission 24 00 022. Pull torque converter out of primary pump carefully with Special Tool 24 4 000. Important! Escaping ATF!  24 00 022 24 00 022

|  |

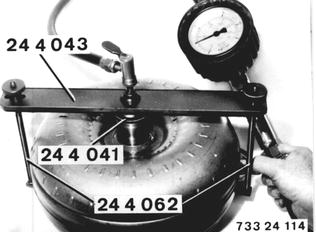

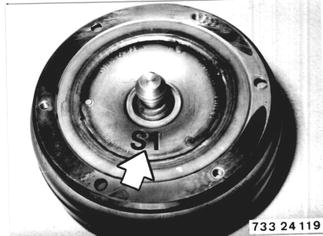

Installation: Check torque converter for leaks with Special Tools 24 4 041, 24 4 043 and 24 4 062. Test pressure: 0.5 bar (7 psi). Important! Always use Special Tool 24 4 043 to prevent injury. |  |

Torque converter must be replaced when bearing surface on converter shaft is damaged. |  |

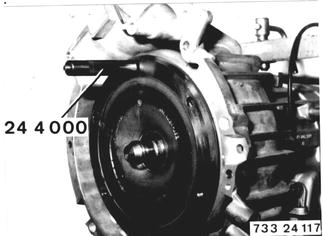

Turn slightly to guide openings on converter into primary pump carefully, using Special Tool 24 4 000. Important! Be careful not to damage converter bearings and seal while guiding in. Converter is in its correct installed position, if drive ring is below case edge. |  |

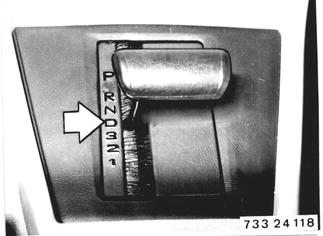

Checking Installed Torque Converter: Engine and transmission oil must have operating temperature. Engine must produce full rated power. Start engine. Pull on parking brake and operate brake pedal fimly. Move selector lever to D and press accelerator pedal to full throttle. Read stall speed* from tachometer.  * See Specifications * See Specifications

|  |

Important! Never test stall speed longer than 10 seconds to prevent damage from excessive heat. Stall Speed Much Above Specified Value*. a) Converter oil volume insufficient - correct oil level. b) Slip in clutches - check clutches. Stall Speed Much Below Specified Value*. a) Engine power insufficient - check engine. b) Converter on pump defective - replace converter or check pump. Torque converters cannot be cleaned with conventional workshop equipment and must be replaced when a transmission had been defective or an oil filter screen torn. Converter identification*.  * See Specifications * See Specifications

|  |

BMW 628csi - M635csi (M6)»24 - Transmission-automatic»24 40 003 - Torque converter - remove and install