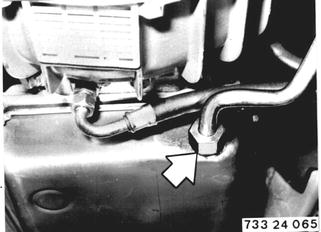

Vehicles after change point in 1982 REMOVING AND INSTALLING OIL SUMP Drain oil. Important! Never reuse drained oil. Installation: The transmission will have to be disassembled, if the oil smells burnt and is black. Unscrew oil filler tube on oil sump. Unscrew oil sump. |  |

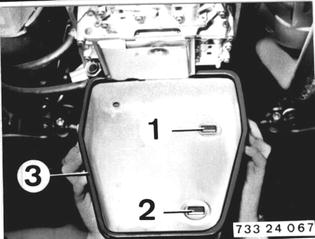

Installation: Mount oil sump with brackets in such a manner, that short leg presses on oil sump. Tightening torque*. Important! The two brackets with straight legs must be mounted on the sides.  *See Specifications *See Specifications

|  |

Clean oil pan. Important! Place magnets (1 and 2) in oil sump. Install gasket (3). |  |

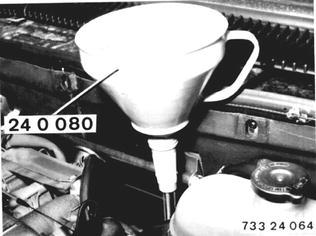

Pour in oil*. Important! Only pour in transmission oil with Special Tool 24 0 080 (funnel).  * See Specifications * See Specifications

|  |

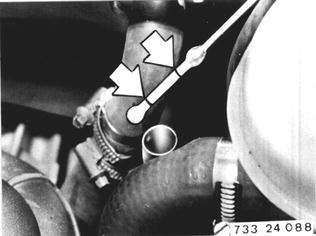

Test drive car. Check oil level. Park car on level floor or ground. Correct oil level in selector lever position P with transmission at operating temperature and engine running at idle speed. Oil level of transmission at operating temperature = approx. 80°C (175°F) mut be between both marks. Amount of oil between min. and max. marks = approx. 0,3 Liter (0,6 pint). |  |

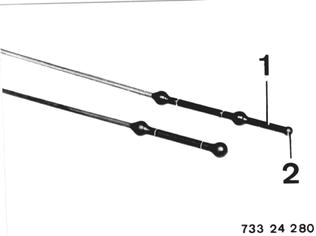

An oil dipstick with a longer measuring tip (1) is standard since 2.85. This produces an earlier dsplay of the oil lever in the transmission. The oil level must not be below ball (2) after a test drive and an oil temperature of approx. 40°C (105°F). The oil level must be between min. and max. marks with an oil temperature of approx. 80°C (175°F). Correct oil level, if necessary. Note: The new oil dipstick can be installed retroactively. Oil Level Too High: Strong foaming, splash loss, high temperature when driving fast, oil lost via vent. Oil Level Too Low: Valves rattlind, foaming, engine slipping, general operating disturbances. |  |