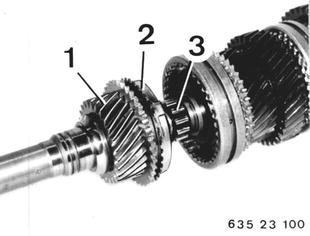

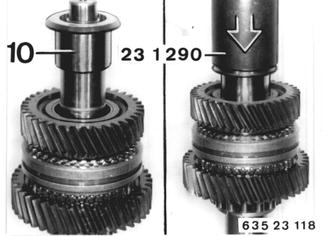

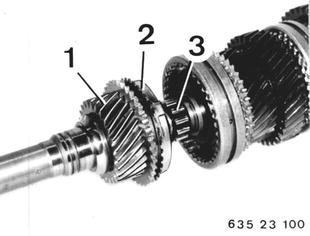

Vehicles after change point in 1982 REPLACING OUTPUT SHAFT - Otuput Shaft Removed - Pull off input shaft (1), synchromesh ring (2) and needle bearing (3). |  |

Lift out circlip (4). Take off shim (5). |  |

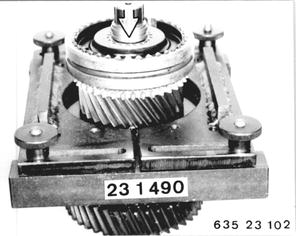

Press off the 3rd gear wheel with guide and sliding sleeves with Special Tool 23 1 490. Take off the needle bearing. Pressing-off force*.  * See Specificatiions * See Specificatiions

|  |

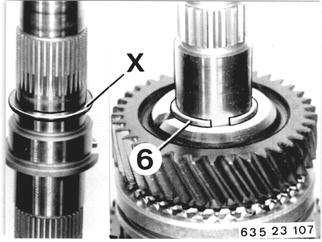

Lift out circlip (6). Installation: Replace circlip. |  |

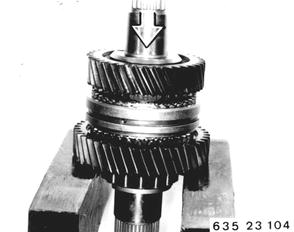

Press 2nd gear wheel, guide sleeve and 1st gear wheel off of the output shaft. |  |

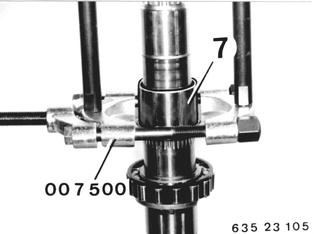

Pull collar (7) off of the output shaft with Special Tool 00 7 500. |  |

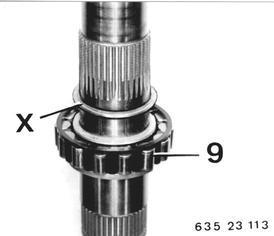

Take off shim (X) and roller bearing (8). |  |

Important! Determine the thickness of shim (X) and circlip (6) before installation of the gear wheel set. Parts can supply shims in thicknesses from 0.3 to 0.5 mm (0.012 to 0.020´´) and circlips from 1.7 to 1.9 mm (0.067 to 0.075´´). |  |

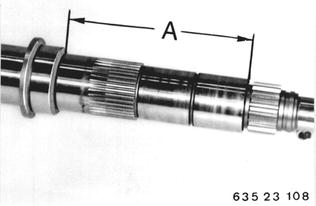

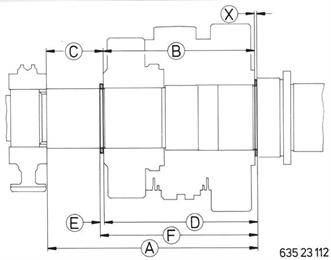

Determine thickness of shim X. Measure distance (A) from collar of 3rd/4th gear guide sleeve to bearing surface of 1st gear collar; for example: 128.3 mm (5.051´´). |  |

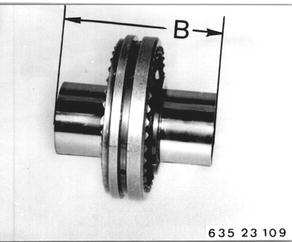

Assemble the 1st gear collar, 1st/2nd gear guide sleeve and 2nd gear collar. Measure distance (B); for example: Example: ..A = 128.3 mm (5.051´´) - B = 93.1 mm (3.665´´) ___________________ ..........35.2 mm (1.386´´) - C = 34.7 mm (1.366´´) ___________________ ..X = 0.5 mm /0.020´´) shim thickness |  |

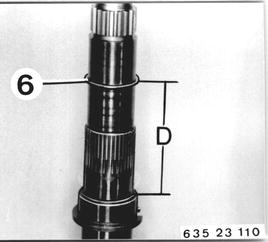

Determine thickness of circlip (6). Install old circlip in groove. Measure distance (D) from bearing surface of 1st gesr collar to lower edge of the circlip. This requires that the circlip is pressed tight in the groove. For example: 93.6 mm (3.685´´). |  |

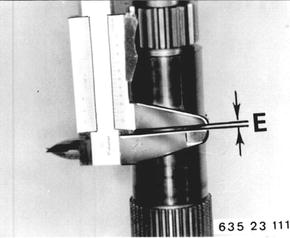

Measure thickness (E) of old circlip. For example: 1.9 mm (0.075´´). Example: .. D = 93.4 mm (3.677´´´) + E = 1.9 mm (0.075´´) ___________________ .. F = 95.3 mm (3.752´´) |  |

Example: .. B = 93.1 mm (3.665´´) + X = 0.5 mm (0.020´´) ___________________ .. G = 93.6 mm (3.685´´) .. F = 95.3 mm (3.752´´) - G = 93.6 mm (3.685´´) __________________ .. E = 1.7 mm (0.067´´) circlip thickness |  |

Install roller bearing (9) with the small diameter end of the plastic cage facing the collar. Install shim X of determined thickness. |  |

Heat collar (7) to about 80°C (175°F) with a hot air blower. Install collar. |  |

Install the split needle bearing, 1st gear wheel and synchromesh ring on the output shaft. |  |

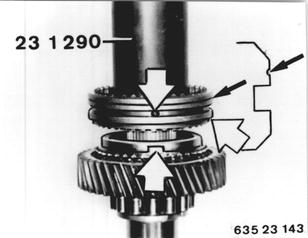

Install 1st/2rd gear guide sleeve with the identification groove facing the 2nd gear wheel. Press on guide sleeve to fit tight with Special Tool 23 1 290. Pressing-on force*. Important! Make sure tabs on synchromesh ring are aligned with openings in guide sleeve while pressing on.  * See Specifications * See Specifications

|  |

Install synchromesh ring, needle bearing and 2nd gear wheel. |  |

Heat collar (10) to about 80°C (175°F) with a hot air blower. Install collar on the output shaft, pressing on to fit tight with Special Tool 23 1 290 if necessary. Turn the 2nd gear wheel to prevent seizure of the needle bearing. |  |

Install circlip (6) of determined thickness. |  |

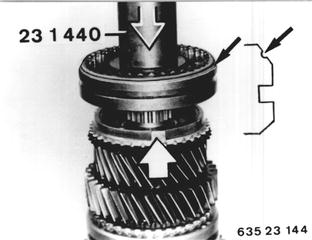

Install needle bearing, 3rd gear wheel and synchromesh ring. Install 3rd/4th gear guide sleeve with the identification groove facing the 4th gear wheel and press on with Special Tool 23 1 440. Important! Tabs on synchromesh ring must be aligned with openings in guide sleeve. |  |

|

|

|

|

|

|

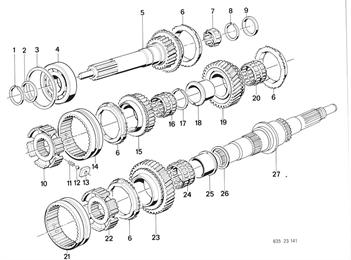

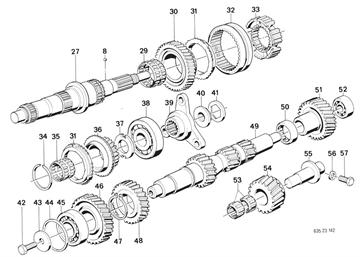

GEAR WHEEL SET WITH BEARINGS 1 Circlip 2 Shim 3 Shim 4 Bearing 5 Input shaft with 4th gear wheel 6 Synchromesh ring 7 Needle bearing 8 Circlip 9 Shim 10 Guide sleeve 11 Spring 12 Ball 13 Drive dog 14 Operating sleeve 15 3rd gear wheel 16 Needle bearing 17 Circlip 18 Shim 19 2nd gear wheel 20 Needle bearing 21 Operating sleeve 22 Guide sleeve 23 1st gear wheel 24 Needle bearing 25 Shim 26 Shim 27 Output shaft |  |

GEAR WHEEL SET WITH BEARINGS 27 Output shaft 28 Ball 29 Needle bearing 30 Reverse gear wheel 31 Synchromesh ring 32 Operating sleeve 33 Guide sleeve 34 Circlip 35 Needle bearing 36 5th gear wheel 37 Thrust washer 38 Ball bearing 39 Output flange 40 Collar nut 41 Lockplate 42 Bolt 43 Washer 44 Shim 45 Ball bearing 46 4th gear wheel 47 Circlip 48 3rd gear wheel 49 Layshaft 50 Roller bearing 51 5th gear wheel 52 Roller bearing 53 Needle bearing 54 Reverse gear 55 Shaft 56 Spring washer 57 Bolt |  |