| |

REPLACING FRONT END ASSEMBLY

Read "Introduction"!

Remove engine hood, both side panels, radiator,

engine with transmission and front axle assembly,

battery, engine oil cooler, exhaust system, propeller

shaft, brake lines and fuel lines in engine

compartment, relay/fuse carrier and wire harness,

speedometer shaft, pedal assembly base, ignition

coil, windshield washer tank, power steering

tank, windshield, instrument panel trim, front

bumper, all radiator grill sections, both double

headlights, both horns, windshield wipers, rain

moldings, engine hood locks, carpet in passenger

compartment and noise insulation on engine firewall.

Check and adjust front and rear axle alignment.

Bleed brakes and clutch.

Adjust engine idle speed and fuel/air mixture.

Aim headlights.

Stamp chassis number and transfer data plate.

| |

| |

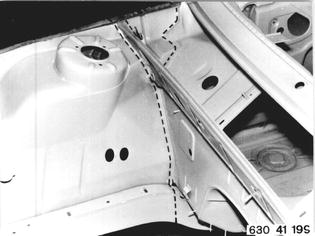

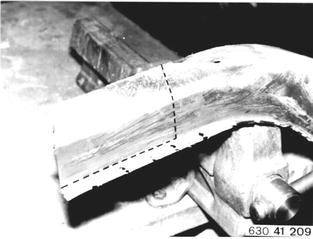

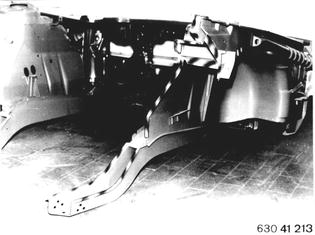

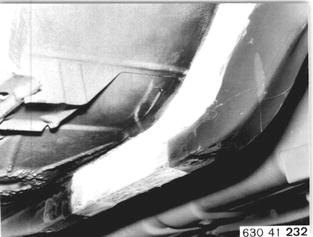

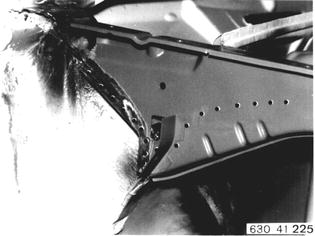

Cut off front end along line.

|  |

| |

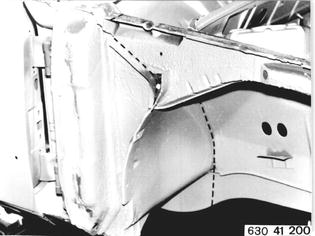

Cut off front end along line.

|  |

| |

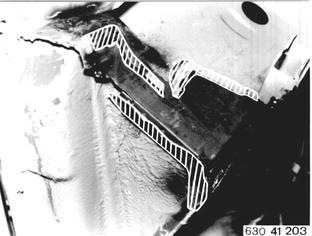

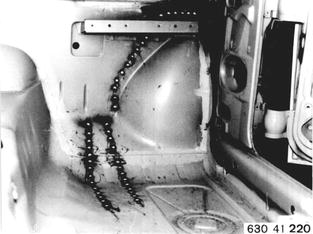

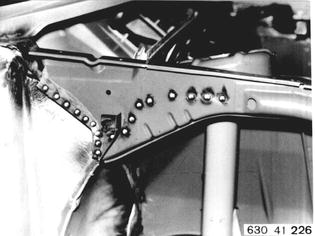

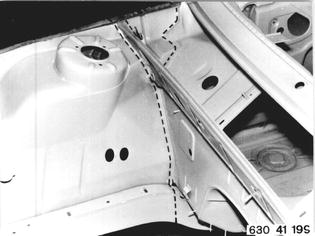

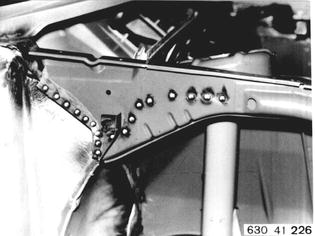

Drill out welding spots from wheel house remainder.

|  |

| |

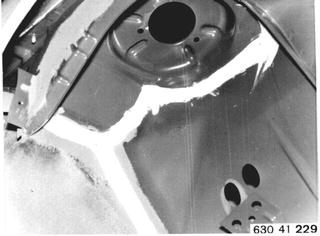

Remove scrap metal.

|  |

| |

Remove scrap metal.

|  |

| |

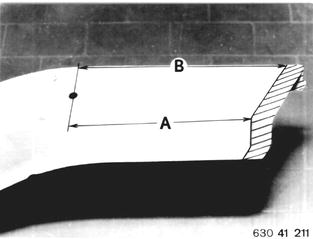

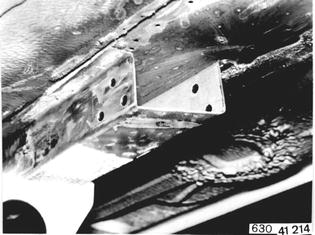

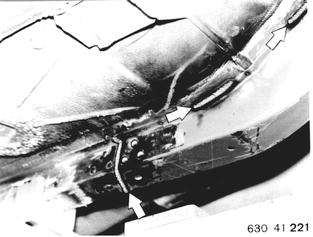

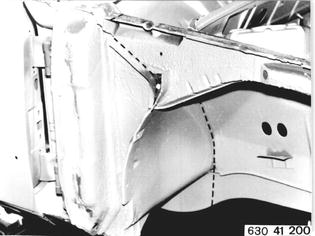

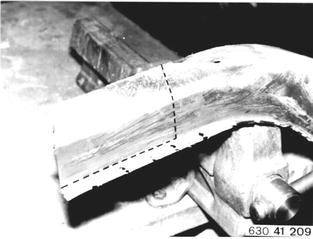

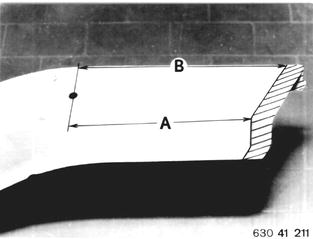

Make cuts in engine carrier.

Distance A = 190 mm (7.480´´)

Distance B = 225 mm (8.858´´)

|  |

| |

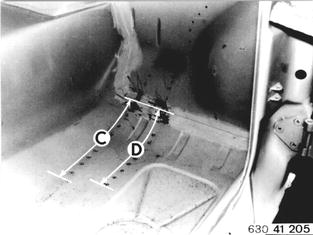

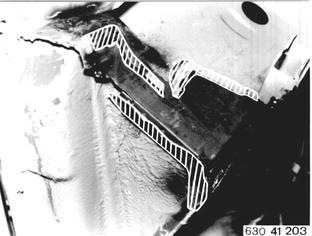

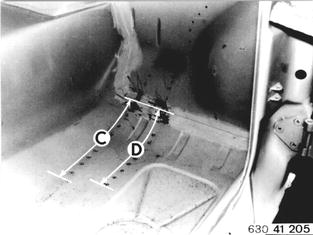

Take off insulation sheet and drill out welding

spots from engine carrier.

Distance C = 320 mm (12.598´´)

Distance D = 280 mm (11.024´´)

|  |

| |

Grind off welding seams and remove section of

engine carrier.

|  |

| |

Align mating surfaces and grind bright on both

sides.

|  |

| |

Align mating surfaces and grind bright on both

sides.

|  |

| |

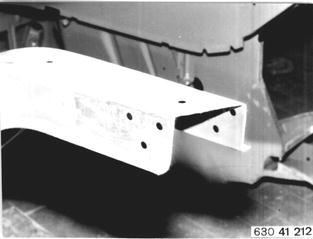

Cut off approx. 120 mm (4.724´´) from

removed section of engine carrier and prepare

as a reinforcement.

|  |

| |

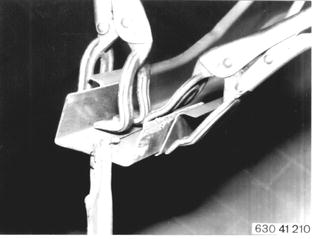

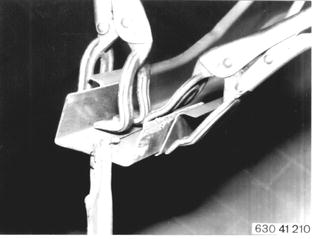

Cut apart U-section member and cut off piece

equalling twice thickness of sheet metal.

Position U-section member in new engine

carrier and tack weld.

|  |

| |

Cut off engine carrier from new front end

custom fit.

Distance A = 190 mm (7.480´´)

Distance B = 225 mm (8.858´´)

|  |

| |

Use 8 mm (0.315´´) dia. drill bit to drill 3

holes from each side and 1 hole from bottom

in area of reinforcement.

|  |

| |

Grind mating surfaces on new front end bright

from both sides.

|  |

| |

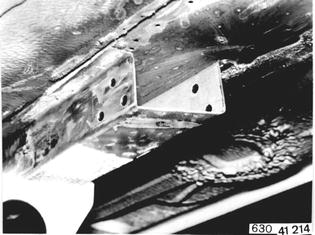

Prepare engine carrier section not removed.

Use 8 mm (0.315´´) dia. drill bit to drill 3 holes

from each side and 1 hole from bottom in area

of reinforcement.

|  |

| |

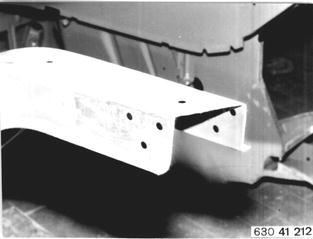

Push in reinforcing U-section members in

remaining section of engine carrier by approx.

60 mm (2 3/8´´) and inert gas plug weld.

|  |

| |

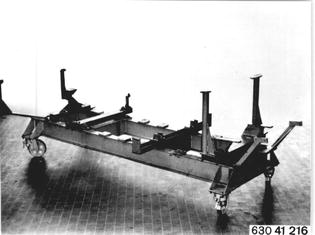

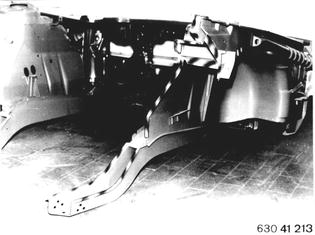

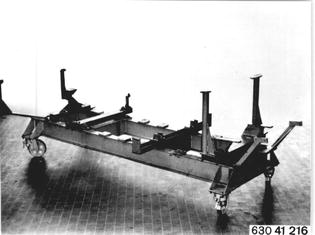

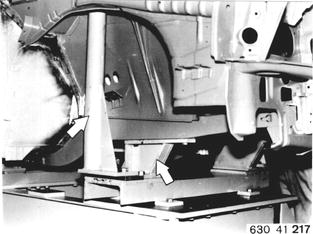

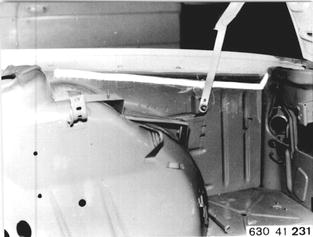

Mount body on straightening bench.

|  |

| |

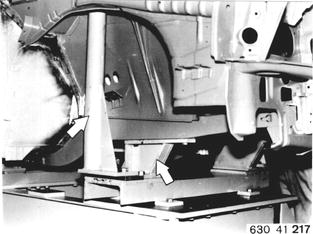

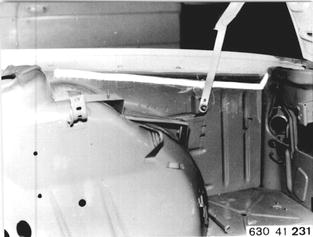

Tack weld front end to body.

Bolt attachments for spring struts and front

axle to straightening bench and front end.

|  |

| |

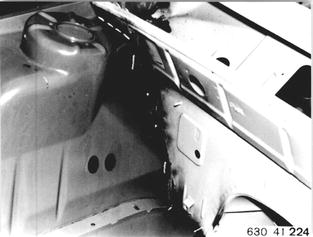

Tack weld wheel housings to firewall.

|  |

| |

Tack weld engine carrier.

|  |

| |

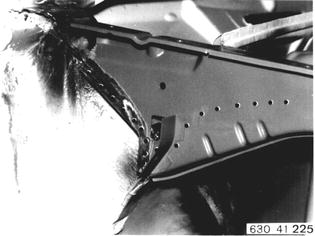

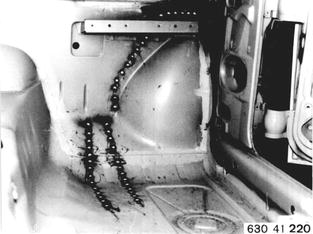

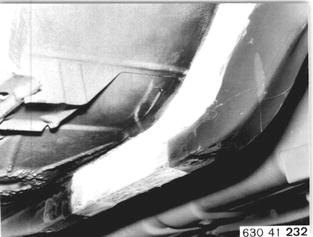

Inert gas plug weld engine carrier and wheel

housings to floor plate and firewall.

|  |

| |

Inert gas weld and inert gas plug weld engine

carrier.

|  |

| |

Inert gas weld wheel housings to firewall.

|  |

| |

Braze guide tube for engine hood cable.

Inert gas weld heater wall to wheel housings.

|  |

| |

Inert gas weld heater wall and wheel housings.

|  |

| |

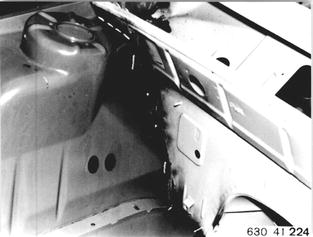

Drill holes in wheel house outer panels for

inert gas welding.

|  |

| |

Inert gas plug weld wheel house outer panels.

Grind down all welding seams and coat with

zinc dust paint.

|  |

| |

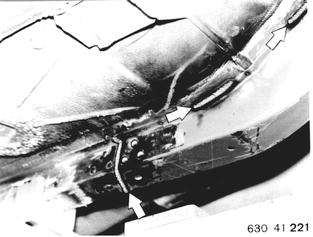

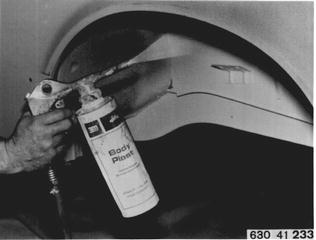

Coat wheel house/firewall joint with special

sealant for joints.

|  |

| |

Coat wheel house/firewall joint with special

sealant for joints.

|  |

| |

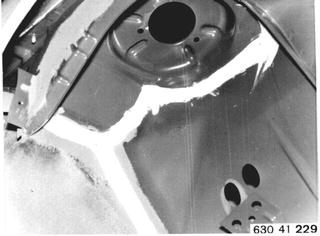

Coat spring strut shell with special sealant for

joints.

|  |

| |

Coat wheel house/firewall joint with special

sealant for joints.

|  |

| |

Coat wheel house joint with special sealant for

joints.

|  |

| |

Coat engine carrier/floor plate joint with special

sealant for joints.

Spray an anti-drumming agent on all joints and

wheel housings.

|  |

| |

Vehicles after change point in 1982

REPLACING COMPLETE FRONT

END

Refer to information on page 41 - 001.

Remove engine hood, both side panels, radiator,

engine complete with transmission and

front axle, battery, engine oil cooler, exhaust

assembly, propeller shaft, brake lines and fuel

lines in engine compartment, central electric

board and wire harness, speedometer drive

cable, pedal assembly base, ignition coil,

washing fluid tank, power steering tank,

complete windshield, instrument panel trim,

complete front bumper, all radiator grill

sections, both double headlights, both horns,

windshield wipers, rain molding strips, engine

hood locks, carpet in passenger compartment

and insulation sheet on engine compartment

wall.

Checking and adjusting front and rear wheel

alignment.

Bleeding brakes and clutch.

Adjusting engine idle speed and fuel/air

mixture.

Aiming headlights.

Die stamping chassis number and transfering

data plate.

| |

| |

Cut off front end along line.

|  |

| |

Cut off front end along line.

|  |

| |

Drill off welding spots on remaining wheel

house panel.

|  |

| |

Remove scrap metal.

|  |

| |

Remove scrap metal.

|  |

| |

Cut into engine carrier.

Distance A = 190 mm (7.480´´)

Distance B = 225 mm (8.858´´)

|  |

| |

Loosen insulation plate and drill off welding

spots on engine carrier.

Distance C = 320 mm (12.598´´)

Distance D = 280 mm (11.024´´)

|  |

| |

Grind off welding seams and remove piece

of engine carrier.

|  |

| |

Straighten and grind both sides of mating

surfaces.

|  |

| |

Straighten and grind both sides of mating

surfaces.

|  |

| |

Cut off approx. 120 mm (4.724´´) from cut out

piece of engine carrier and prepare as reinforcement

panel.

|  |

| |

Cut U-section apart and cut off twice the sheet

metal thickness.

Place and tack weld U-section in new engine

carrier.

|  |

| |

Cut off engine carrier from new front end to

size.

Distance A = 190 mm (7.480´´)

Distance B = 225 mm (8.858´´)

|  |

| |

Drill three holes from each side in area of

reinforcement and one hole from below.

Hole dia. = 8 mm (0.315´´).

|  |

| |

Grind both sides of mating surfaces on new

front end.

|  |

| |

Prepare old piece of engine carrier.

Drill three holes from each side in area of

reinforcement panel and one hole form below.

Hole dia. = 8 mm (0.315´´).

|  |

| |

Slide reinforcement U-section into old piece

of engine carrier approx. 60 mm (2.362´´) and

inert gas plug weld.

|  |

| |

Set up body on straightening bench.

|  |

| |

Tack weld front end on body.

Bolt attachments for spring struts and front

axle on straightening bench and front end.

|  |

| |

Tack weld wheel houses on firewall.

|  |

| |

Tack weld engine carrier.

|  |

| |

Inert gas plug weld engine carrier and wheel

houses on floor plate and firewall.

|  |

| |

Inert gas weld and inert gas plug weld engine

carrier.

|  |

| |

Inert gas weld wheel houses on firewall.

|  |

| |

Braze guide tube for engine hood cable.

Inert gas weld heater wall on wheel houses.

|  |

| |

Inert gas weld heater wall and wheel houses.

|  |

| |

Drill holes in wheel house outside panels for

inert gas plug welding.

|  |

| |

Inert gas plug weld wheel house outside panels.

Grind down and coat all welding seams with

zinc dust paint.

|  |

| |

Coat wheel house/firewall joint with joint

sealing compound.

|  |

| |

Coat wheel house/firewall joint with joint

sealing compound.

|  |

| |

Coat spring strut shell jooint with joint sealing

compound.

|  |

| |

Coat wheel house/firewall joint with joint

sealing compound.

|  |

| |

Coat wheel house joint with joint sealing

compound.

|  |

| |

Coat engine carrier/floor plate joint wiht joint

sealing compound.

|  |

| |

Spray anti-drumming compound on all joints

and wheel houses.

|  |