STATIC AND DYNAMIC STATIONARY BALANCING OF WHEEL - Wheel Removed - Remove old balance weights, stones in treads and large pieces of dirt. Balance wheel according to instructions supplied with pertinent wheel balancer. |  |

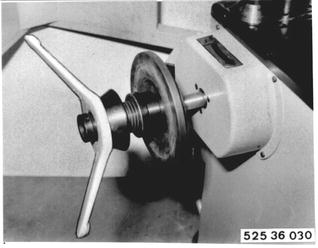

Use suitable centering pin with js 6 tolerance of pertinent wheel balancer. See Service Information 7 01 76 (55) e. |  |

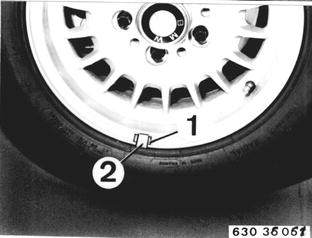

Arrangement of balance weights on cast aluminum rims. 1 = Balance weight 2 = Spring clip Use only one balance weight for up to 60 grams (2 oz.) of unbalance. Note maximum unbalance per wheel and side¹).  ¹) See Specifications ¹) See Specifications

|  |

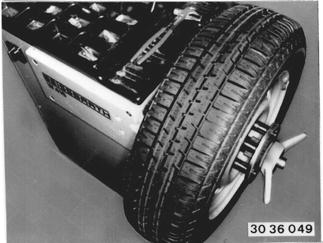

Vehicles after change point in 1982 BALANCING WHEEL DYNAMICALLY - Wheel Removed - Remove old balance weights, stones in tire threads and large pieces of dirt. Check tire inflation pressure and condition of tire (damage or flat spots caused by long down time). If applicable, check wheel and tire for runout before removing - see 36 10 209.  36 10 209 36 10 209

|  |

Balance wheel to operating instructions supplied with pertinent balancing machine. Important! The wheel must be mounted in the same position on the balancing machine and car (e.g. valve facing down). |  |

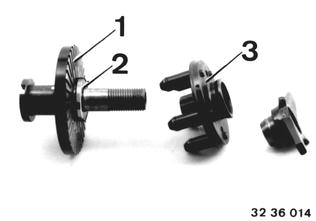

Use suitable center of pertinent balancing machine supplier. Also refer to Service Information bulletins 7 01 81 (831) and 7 01 82 (948). 1 = Basic flange 2 = Center 3 = Type flange Also refer to workshop equipment planning documents. |  |

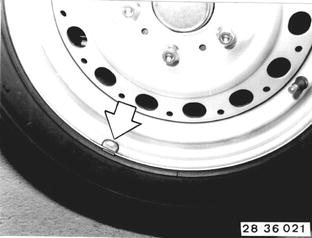

Arrangement of Balance Weights on Steel Wheel Rims: Take up imbalance up to 70 grams with one and above 70 grams with two balance weights. Check maximum imbalance per wheel* and side*.  * See Specifications * See Specifications

|  |

Arrangement of Balance Weights on Aluminum Wheel Rims: 1 = Balance weight 2 = Spring clip Take up imbalance up to 60 grams with only one balance weight. Check maximum imbalance per wheel* and side*. Note: Cemented balance weights may only be used once - remove plastic sheet prior to installation.  * See Specifications * See Specifications

|  |

|

BMW 628csi - M635csi (M6)»36 - Wheels and tyres»36 10 508 - Wheel - static and dynamic stationary balancing