REMOVING AND INSTALLING FRONT OR REAR WHEEL Loosen wheel bolts. Important: Wheel was electronically balanced. Before removing, mark location of wheel to wheel hub with a scribe or chalk mark. Installation: Tightening torque¹). Apply light coat of lubricant to wheel bolts before installing. Coat centering pin with high temperature proof grease or a lubricating/corrosion inhibiting product.  ¹) See Specifications ¹) See Specifications

|  |

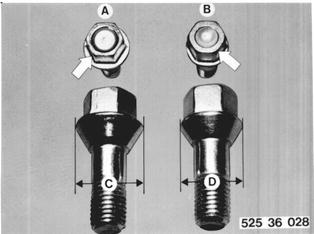

Important: Wheel bolts A = aluminum rims. Wheel bolts B = steel rims. External Identification: Cylindrical milling on wheel bolts A. Spherical milling on wheel bolts B. Taper diameter of wheel bolts A = C 23 + 0.5 mm (0.905 + 0.020´´). Taper diameter of wheel bolts B = D 21 + 0.5 mm (0.827 + 0.020´´). Wheel bolts for steel rims must not be used on aluminum rims. |  |

Vehicles after change point in 1982 REMOVING AND INSTALLING FRONT OR REAR WHEEL If applicable, remove wheel bolt cover. Loosen wheel bolts. Important! Wheel was balanced electronically - mark wheel to wheel hub position before removing. |  |

Installation: Clean centering collar of wheel hub and bearing surfaces of wheel rim to remove dirt and old grease before mounting a wheel and coat the center with Plastilube**. Check wheel bolt threads and tapers for wear, replacing wheel bolts if necessary. Give wheel bolt threads a light coat of grease, the tapered part however must not be coated with grease.  ** Source: HWB ** Source: HWB

|  |

Tighten wheel bolts crosswise. Tightening torque*. If new wheel rims are installed for the first time, recheck tightening torque* after 1,000 km (600 miles).  * See Specifications * See Specifications

|  |

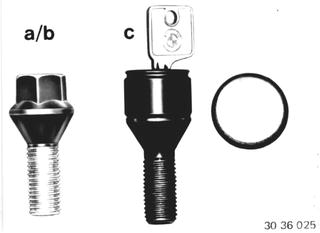

Wheel bolts can be used for either steel or aluminum wheel rims sinse 9.82. a) Wheel bolt - galvanized b) Wheel bolt - black chrome plated c) Wheel bolt - black chrome plated and lockable (special equipment) |  |

BMW 628csi - M635csi (M6)»36 - Wheels and tyres»36 10 300 - Wheel, front or rear - removing and installing