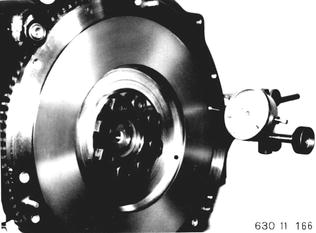

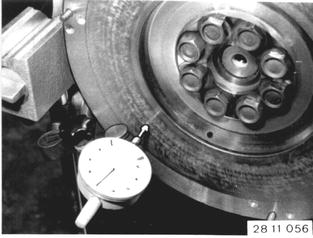

REMOVING AND INSTALLING FLYWHEEL Remove clutch 21 21 000. Check flywheel´s axial runout¹).  21 21 000 21 21 000 ¹) See Specifications ¹) See Specifications

|  |

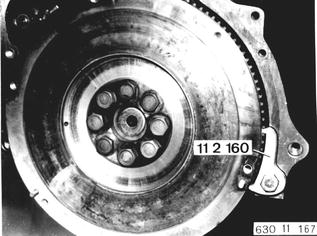

Hold flywheel with Special Tool 11 2 160. Unscrew stretch bolts. Installation: Be sure to replace stretch bolts and to install new ones with Loctite No. 270. Remove flywheel. |  |

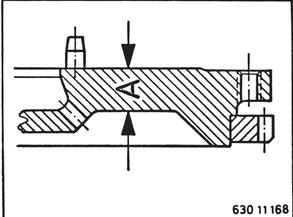

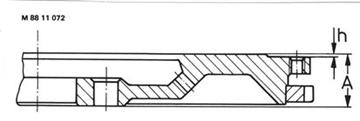

Installation: Friction surfaces can be ground¹). But wall thickness within friction area must not be ground to less than A = 13,5 mm (0.531´´).  ¹) See Specifications ¹) See Specifications

|  |

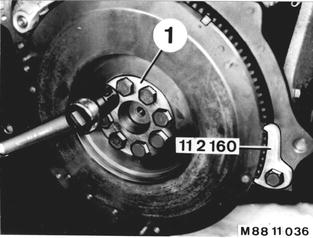

Vehicles after change point in 1982 REMOVING AND INSTALLING FLYWHEEL Remove clutch disc 21 21 000. Hold flywheel with Special Tool 11 2 160. Unscrew vbolts and take off flywheel. Installation: Clean tapped bores. Insert ring (1). Replace and install expansion bolts with Loctite No. 270**. Tightening torque*.  * See Specifications * See Specifications 21 21 000 21 21 000 ** Source: HWB ** Source: HWB

|  |

|

|

Friction surface may be machined to minimum thickness A*. If machining the friction surface reduces distance "h" to zero, the flange surface distance "h" has to be machined.  * See Specifications * See Specifications

|  |