|

|

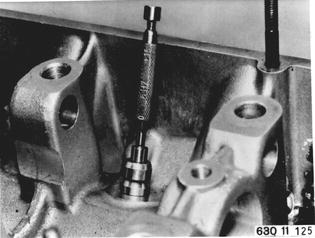

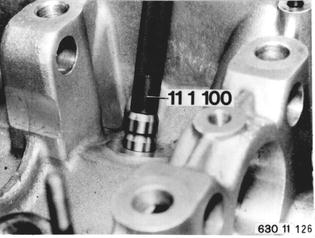

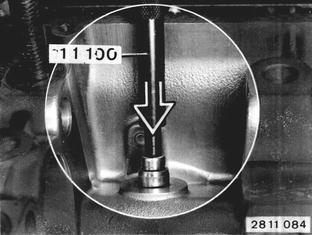

If permissible wear limits are exceeded, drive out valve guide cold with Special Tool 11 1 100. |  |

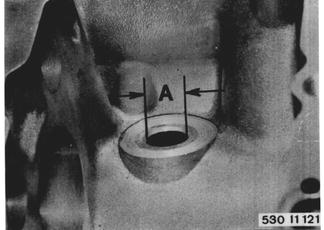

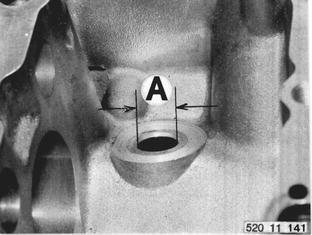

Check bore in cylinder head. If permissible diameter A is exceeded, ream out bore and install an oversize¹) valve guide.  ¹) See Specifications ¹) See Specifications

|  |

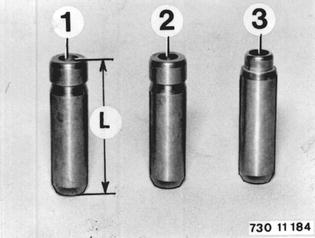

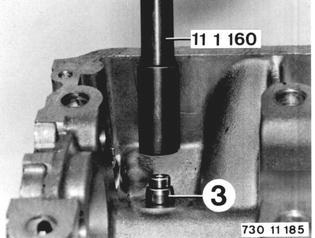

Important - Installation: Modified valve guides. Watch total length L¹). Use modified valve seal for valve guide (3).  ¹) See Specifications ¹) See Specifications

|  |

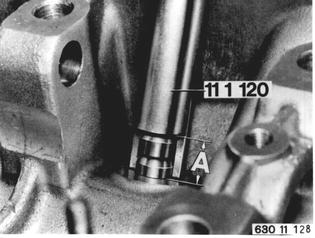

Heat¹) cylinder head. Tapered groove faces camshaft. Knock valve guide into combustion chamber from the camshaft side with Special Tool 11 1 120. Bore in Special Tool 11 1 120 determines protrusion A¹). Important: Insert a 1.5 mm (0.060´´) thick washer in Special Tool 11 1 120 for shorter valve guide (2).  ¹) See Specifications ¹) See Specifications

|  |

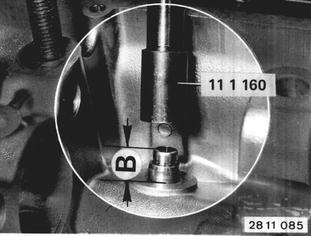

Important: Use Special Tool 11 1 160 for stepped valve guide (3). Bore in special tool determines amount of protrusion¹). Ream out valve guide to specified inside diameter¹). Machine valve seats 11 12 607.  ¹) See Specifications ¹) See Specifications 11 12 607 11 12 607

|  |

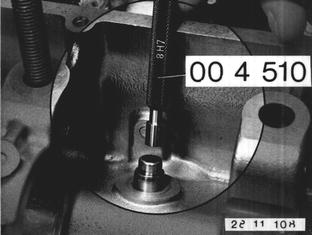

Vehicles after change point in 1982 REPLACING VALVE GUIDE - Valve Removed - Check valve guide wear* with Special Tool 00 4 510. |  |

Drive out valve guide (cold) with Special Tool 11 1 000. |  |

Check bore cylinder head with Special Tool 00 4 520. Ream out bore with a standard reamer and install an oversize* valve guide, if permissible diameter (A) is exceeded.  * See Specifications * See Specifications

|  |

Heat cylinder head*. Drive valve guide into cylinder head from the camshaft side with Special Tool 11 1 160. Stepped end of valve guide faces camshaft. Important! Bore in special tool determines protrusion B* of valve guide. Ream out valve guide to specified inside diameter* with Special Tool 00 4 500. Machine valve seats - see 11 12 607.  * See Specifications * See Specifications 11 12 607 11 12 607

|  |