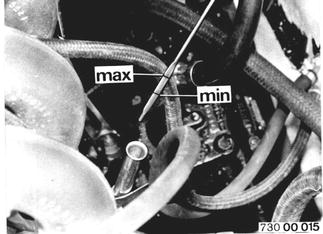

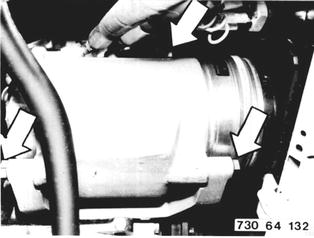

Checking/Correcting Engine Oil Level Requirements: Car on level surface. Add oil to raise level to max. mark at most. Amount of oil between min. and max. marks: 1.5 ltr. (3 pints). Refer to Service Information of Group 11 for approved oils.  11 000 000 11 000 000

|  |

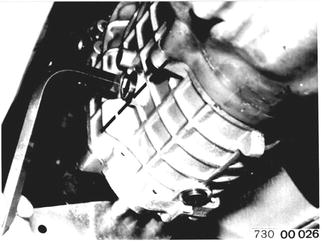

Checking/Correctiong Manual Transmission Oil Level Unscrew oil filter plug. Add oil to raise level to lower edge of filter opening. Refer to Service Information of Group 23 for approved oils. Installation: Check filler plug, replacing if necessary. Tightening torque¹).  ¹) See Specifications of Groups 23 and 24 ¹) See Specifications of Groups 23 and 24 ¹) See Specifications of Groups 23 and 24 ¹) See Specifications of Groups 23 and 24

|  |

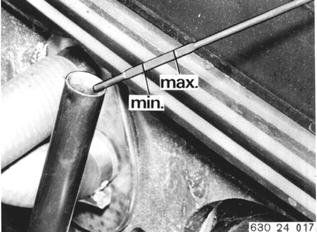

Checking/Correcting Automatic Transmission Oil Level Requirments: Car on level surface. Transmission at operating temperature. Selector lever at "P". Engine running at idle speed. Amount of oil between min. and max. marks: Flat oil pan = approx. 0.25 ltr. (0.5 pints) Deep oil pan = approx. 0.40 ltr. (0.8 pints) Important: Never wipe off dipstick with a cloth losing lint. Refer to Service Information of Group 24 for approved ATF. Add ATF through funnel 24 0 080.  24 00 000 24 00 000

|  |

Checking Power Steering Oil Level With engine stopped, unscrew winged nut and take off tank cover. Oil level should be approx. 5 mm (0,.2´´) above mark on tank wall. Start engine and, if necessary, add oil until level agrees with mark, Refer to Service Information of Group 32 for approved oils.  32 00 000 32 00 000

|  |

Checking/Correcting Final Drive Oil Level Unscrew oil filler plug. Add oil to raise level to lower edge of filler opening. Refer to Service Information of Group 33 for approved oils. Installation: Check seal, replacing if necessary. Tightening torque¹).  33 00 000 33 00 000 ¹) See Specifications of Group 33 ¹) See Specifications of Group 33

|  |

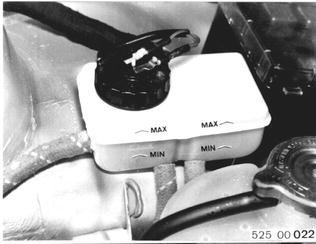

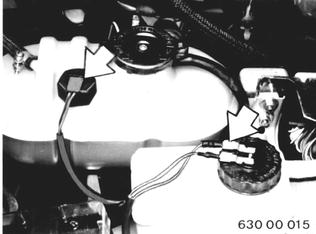

Checking/Correctiong Brake Fluid Level Brake fluid level must be between min. and max. marks in transparent tank for brake system. Add brake fluid to raise level to max. mark. Refer to Service Information of Group 34 for approved brake fluids. Inportant: Replace brake fluid annually.  34 00 000 34 00 000

|  |

Checking/Correcting Battery Acid Level Lift off battery cover and unscrew caps. Acid level should be approx. 5 mm (0.2´´) above upper edge of plates in each cell or up to level mark visible in opening. Add distilled water, if level is too low. Keep top surface of battery dry and clean. Important: Be careful not to get acid and lead oxide from battery poles on clothing. Never work with an open flame near batteries. Danger of explosion! |  |

Checking Coolant Level and Concentration Add coolant to raise level to 2 cm (0.8´´) below radiator cap at most. Check antifreeze concentration. All year protection down to -25°C (-13°F). Refer to Service Information of Group 17 for approved antifreezes (longterm) and corrosion inhibitors.  17 00 000 17 00 000

|  |

Checking/Correcting Fluid Level in Windshield Washer Tank The headlight/windshield washing systems can be kept ready for operation down to temperatures of -20°C (-4°F) by adding 40% alcohol. |  |

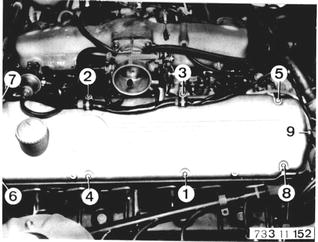

SERVICE JOBS ON ENGINE Tightening Cylinder Head Remove air cleaner housing. |  |

Unscrew cylinder head cover. Installation: Tighten nuts and bolts in order of 1 through 9. |  |

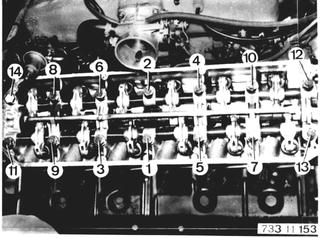

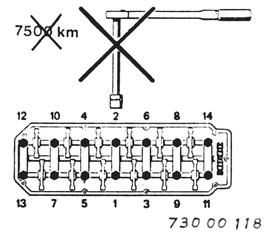

Max. engine temperature: 35°C (95°F). Tighten cylinder head bolts to 78 - 82 Nm (56 to 59 ft. lbs.) one after the other in order of 1 through 14. Important: Never loosen cylinder head bolts; only turn them in "tighten" direction. |  |

Important: The cylinder head bolts are tightened by torque angle in the 600 mile inspection. A pertinent label must be mounted on the valve cover. Any other type of cylinder head tightening is omitted. |  |

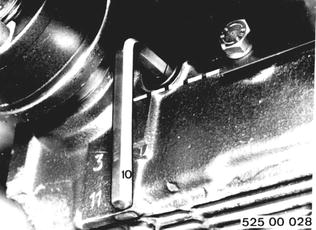

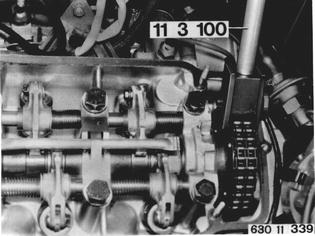

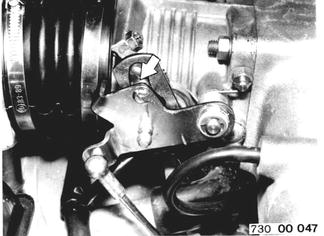

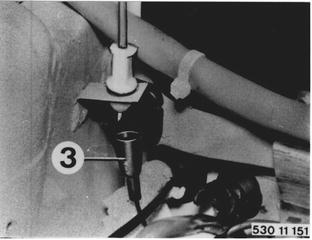

Adjusting Valve Play Turn engine with Special Tool 11 3 100. |  |

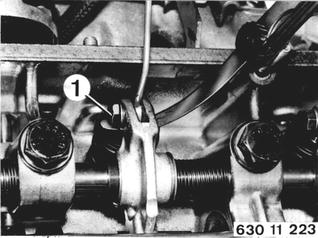

Adjusting order = firing order (1-5-3-6-2-4) in compression top dead center (TDC) Adjust valve play between valve and eccentric after loosening nut (1). Tighten nut (1) with Special Tools 11 1 150 and 00 2 050. Tightening torque¹). Intake and exhaust valve play on cold engine = 0.25 mm (0.010´´).  ¹) See Specifications of Group 11 ¹) See Specifications of Group 11

|  |

Tightening Engine Nuts and Bolts Left and right engine mounts to front axle carrier.....Nm 43-48, Ft.Lbs. 31-35 Left and right engine mounts to support bracket .....Nm 43-48, Ft.Lbs. 31-35 Left support bracket to engine (M8).....Nm 22-24, Ft.Lbs. 16-17 Right support bracket to engine (M10).....Nm 43-48, Ft.Lbs. 31-35 Thermo reactor to cylinder head.....Nm 30-33,Ft.Lbs. 22-24 Intake manifold to cylinder head.....Nm 30-33, Ft.Lbs. 22-24 Upper and lower timing case covers.....Nm 9-11, Ft.Lbs. 6.5-8 Oil pan to crankcase and timing case cover.....Nm 9-11, Ft.Lbs. 6,5-8 | |

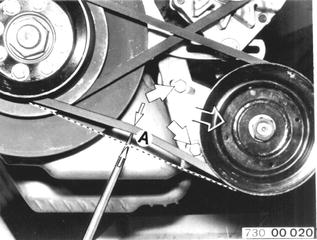

Checking/Correcting Drive Belt Tightness A correctly tightened belt must give by distance (A) = 5 to 10 mm (0.197 to 0.394´´). Tightening Alternator Belt: Loosen alternator at tightening bar and upper mount. Swing out alternator and tighten bolts. |  |

Tightening Power Steering Belt: Loosen pump at holder and press down. Tighten mounting bolts. Open Flank Drive Belts: This type of drive belt should only give by 2 to 3 mm (0.080 to 0.120´´). |  |

Checking/Correcting Tightness of Drive Belt for Air Conditioner Compressor. |  |

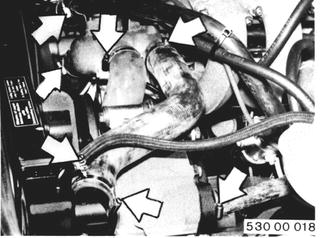

Checking Engine Vent System for Leaks Check gasket in oil filler cap. |  |

Check hose for crankcase breathing for tight fit or damage. |  |

Performing SERVICE TEST Test Program 01 Engine Refer to operating instructions for BMW service test unit. |  |

SERVICE JOBS ON ENGINE ELECTRICAL SYSTEM Important: Carry out all jobs on transistor ignition system only with engine stopped and ignition turned off. DANGER! Checking Tightness of Wire Connections Check wires and plugs on engine for correct routing and tight fit. If necessary, bend wire plugs carefully with a pliers. |  |

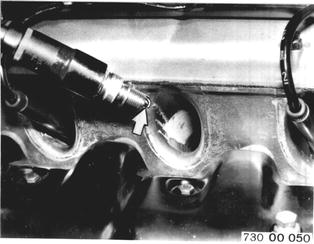

Checking or Replacing Spark Plugs Unscrew spark plugs. Clean or replace spark plugs covered with soot or oil. Electrode gap = 0.6 + 0.1mm (0.024 + 0.004´´). Approved spark plugs¹). Tighetening torque¹). Check spark plug wires and connectors for damage and tight fit.  ¹) See Specifications of Group 12 ¹) See Specifications of Group 12

|  |

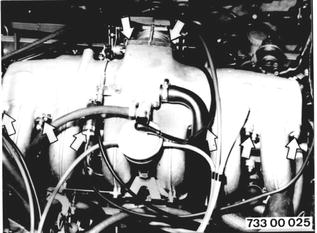

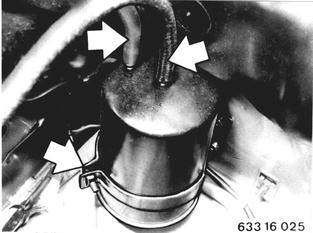

SERVICE JOBS ON FUEL INJECTION SYSTEM Checking Connections for Tightness or Leaks Check tightness of mountings and connections on air flow sensor, throttle housings, air collector, vibration tubes and throttle bypass valve, tightenning if necessary. |  |

Tighten mounting clamps and screws of fuel injector holders. Check lines for correct routing and leaks. |  |

Lubricating Throttle Lever with Oil Check throttle valve for easy movement. Lubricate bearings with oil. Lubricate gate of throttle lever with grease. |  |

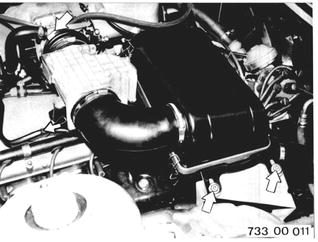

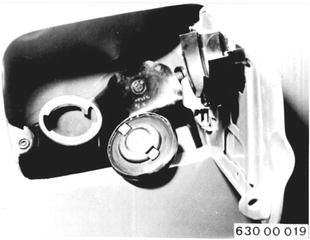

Checking or Replacing Air Filter Cartridge Open fasteners. Remove air filter cartridge. Installation: Watch installed position of the word "TOP". |  |

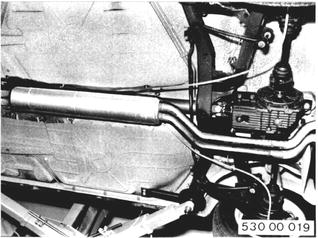

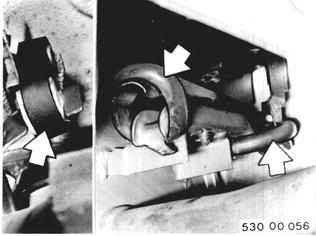

SERVICE JOBS ON EXHAUST SYSTEM Checking Exhaust System Check exhaust system for good condition, correct routing and leaks. |  |

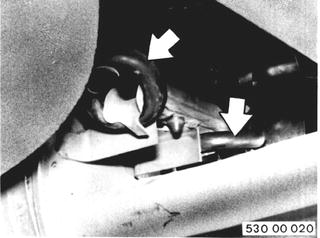

Check condition and tightness of exhaust suspension. |  |

Check heat shields for tight fit or damage. |  |

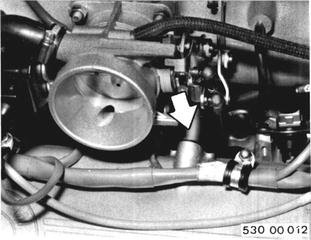

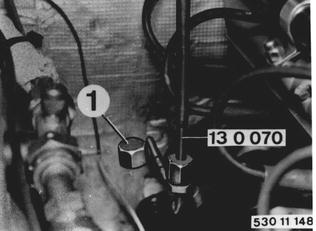

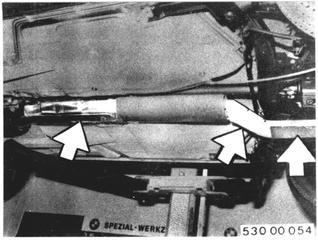

Checking Function of Oxygen Sensor Connect digital tester. Adjust engine idle speed 13 00 054. Unscrew plug nut (1). Install CO tester 13 0 070 in exhaust line. Connect CO tester.  13 00 054 13 00 054

|  |

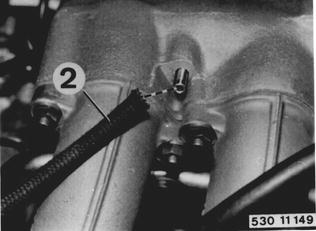

Pull off hose (2) from collector to carbon canister. Don´t plug opening. Measure and note CO level value. CO level must be between 0.2 and 0.8% by volume CO level too low: 1.) Leak in intake system after air flow sensor. Check intake pipes, intake neck, hoses and connections for leaks. 2.) Leak in crankcase. Check valve cover seal, oil pan, oil dipstick and vent line for leaks. |  |

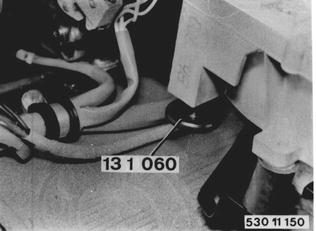

Tighten CO level control screw with Special Tool 13 1 060. This should not change the CO level. Oxygen sensor is defective, if CO level rises. |  |

Disconnect plug (3) for oxygen sensor. Readjust the high CO level to the value measured earlier with the oxygen sensor. Connect plug (3). Important: If car had been operated on leaded gasoline, replace oxygen sensor and catalytic converter. |  |

Checking Fuel Evaporation System Check tightness of hose lines and connections on fuel evaporation system. Check filter plate on carbon filter for plugging, replacing carbon filter if necessary. |  |

Checking Fuel System for Leaks Check tank cap and gasket, fuel tank and lines for leaks or damage (visual inspection). |  |

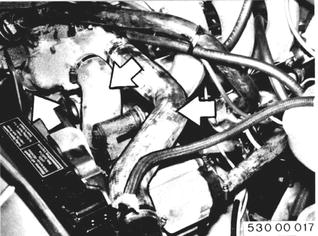

SERVICE JOBS ON COOLING SYSTEM Tightening Hose Clamps on Cooling System Check coolant hoses for damage and correct routing. |  |

Tighten all hose clamps on radiator and engine. |  |

Checking EGR System Includes: Checking function of air pump, coasting blowoff valve, check valve, thermo valve, pressure converter and EGR valve, see 11 70 009.  11 70 009 11 70 009

| |

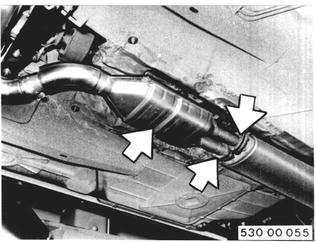

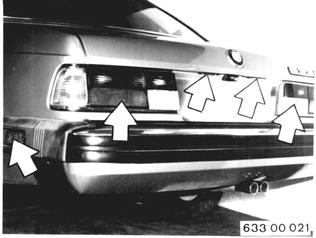

From 1980 Models: Checking Exhaust System Check exhaust system for good condition, correct routing and leaks. Remove heat shields to check joints and gaskets for leaks. Check catalytic converter for external distortion, cracks or rattling. Important: If car had been operated on leaded gasoline, replace catalytic converter and oxygen sensor. |  |

Check condition and tightness of exhaust suspension. |  |

Check screws, nuts and bolts on heat shields and guards for tightness. |  |

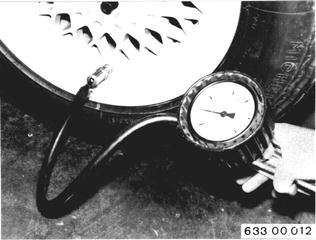

Checking Tire Pressure Values (Including Spare Wheel) Note temperature of tires. Note car load condition. Always take highest pressure for spare wheel tire. Install dust caps. Tire pressure values¹).  ¹) See Specifications of Group 36 ¹) See Specifications of Group 36

|  |

Inspecting Tires Tread depth of tires must not be worn to less than 3 mm (0.120´´) over entire tire width. Check tires for one-sided wear. Check tires and wheel rims for damage and correct size¹) and type.  ¹) See Specifications of Group 36 ¹) See Specifications of Group 36

|  |

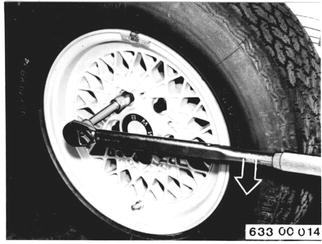

Checking Tightness of Wheel Bolts Check tightness of wheel bolts with a torque wrench. Tightening torque¹).  ¹) See Specifications of Group 36 ¹) See Specifications of Group 36

|  |

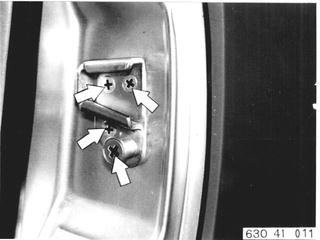

SERVICE JOBS ON BODY Checking Function of Locks Check function and adjustment of locks on doors, engine hood and trunk lid, adjusting if necessary. |  |

Inspecting Chrome and Paint Finish Inspect chrome parts for damage or defects. Check body paint for scratches, dust inclusions and silicone pockets. |  |

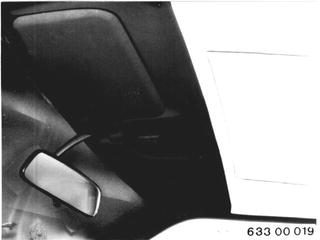

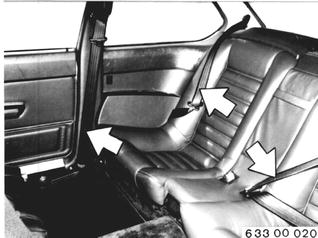

SERVICE JOBS ON BODY EQUIPMENT Checking Interior Equipment Check headliner, trim panels and carpets for correct installation, damage and dirt. |  |

Checking Seat Belts Check that seat belts function correctly, are in good condition and anchored firmly. |  |

SERVICE JOBS ON GENERAL ELECTRICAL SYSTEM Checking Function of Lights Check overnight lights, main and high beam headlights, stop lights, backup lights, rear fog light, license plate light, turn signals, hazard lights and horn for correct function, condensation and damage. |  |

Check function of heater blower, indicator lamps, instrument lights, cigar lighter, inside lamp, glove box lamp, trunk and engine compartment lamps. |  |

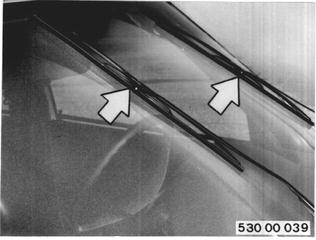

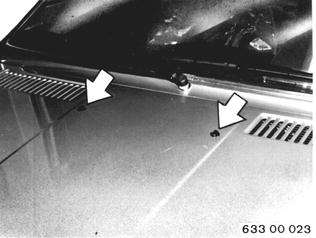

Checking Windshield Wipers Check function of wipe/wash intermittent action switch. Check windshield wiper arms and rubber blades. |  |

Check function of windshield washer system. |  |

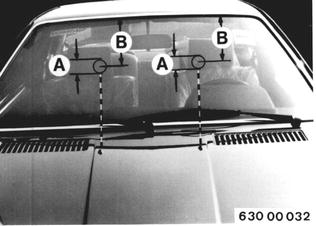

If stream does not hit within circle (A), the spray jet will have to be adjusted. A = 50mm (2´´) B = 200mm (8´´) |  |

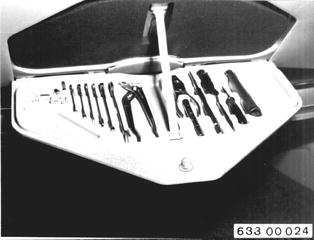

Checking Tools and Documents Supplied with Car Checking for Completeness Check whether contents of toolbox is complete. |  |

@@BCheck whether car has spare keys, owner´s manual, service booklet, list of dealers and warranty cards, as well as car jack and wheel bolt wrench. |  |

Final Inspection During test drive check traffic safety and function of engine, cold start device, cooling system, transmission, final drive, steering and brakes. After adjustment of parking brake, pull up lever by 4 teeth and drive car about 400 m (400 yds.). After test drive check engine, cooling system, transmission, final drive, steering, brakes, radiator cap, fuel tank and lines for leaks. Visually inspect function of air conditioner and flow of refrigerant at receiver/drier sight glass. | |

Check engine idle speed and CO level - see OO-12. |  |

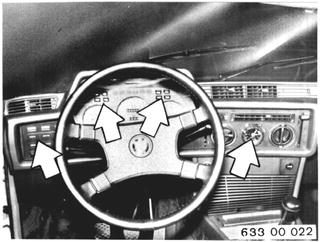

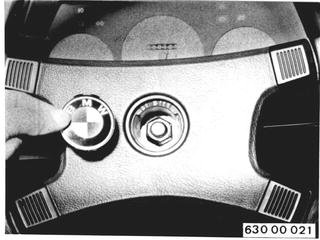

Check steering wheel straight ahead position and, if applicable, reposition steering wheel (not for free transfer inspection). Check steering wheel´s straight ahead position during test drive. To reposition steering wheel remove BMW emblem, unscrew nut, take off steering wheel and install in straight ahead position. Replace self-locking nut. Tightening torque¹),  ¹) See Specifications of Group 32 ¹) See Specifications of Group 32

|  |

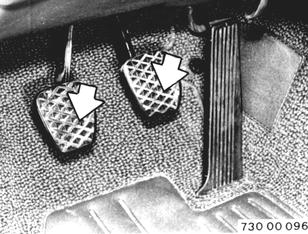

Check clutch controls (not for free transfer inspection). Clutch pedal must not have any mechanical play, e.g. missing bearing bushings. After flooring the clutch pedal and waiting about 3 seconds, it should be possible to engage reverse gear without mechanical noise. Check brakes for one-sided pull or flattering during test drive. Watch indicator lamps. |  |

BMW 628csi - M635csi (M6)»00 - Maintenance and general information»00 00 009 - Free transfer inspection