Vehicles before change point in 1982 DISASSEMBLING AND ASSEMBLING LOCKING DIFFERENTAL (locking differential removed) Unscrew case cover mounting bolts. Take off case cover. |  |

Turn case upside down and let contents slide out. Apply light knocks against case if necessary. |  |

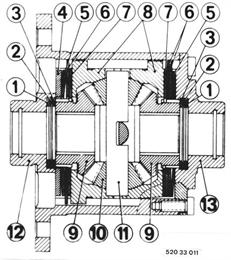

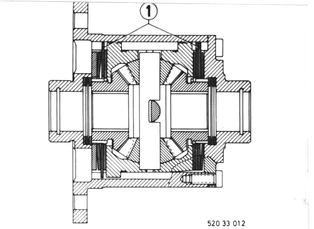

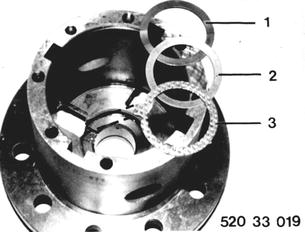

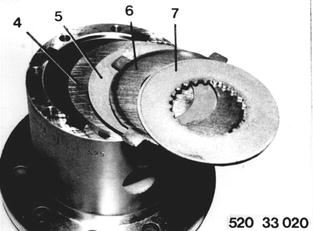

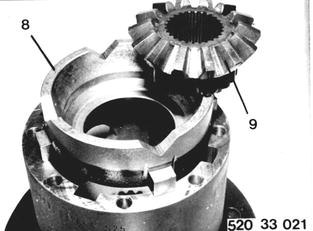

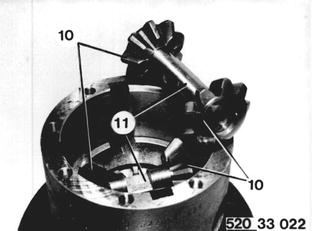

Order of Installation: 1 thrust washer, 2 diaphragm spring, 3 stepped washer, 4 spacer, 5 diaphragm spring, 6 outer plate, 7 inner plate, 8 pressure ring, 9 differential side gear, 10 differential gear, 11 differential shaft, 12 case and 13 cover. Check all parts for scoring. Pressure rings must move easily in case. Guide tabs of pressure rings and outer plates must not be worn. Inner plates must move easily on spline. Splines must not be worn. Replace worn thrust washers, stepped washers and plates. |  |

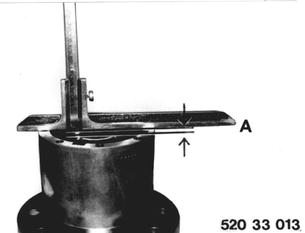

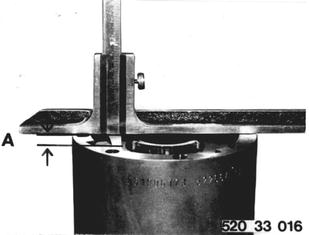

Adjust axial play of differential side gears after replacement of thrust washers and stepped washers. Install following parts in case one after the other. (8) pressure ring, (9) differential side gear, (10) differential gear, (11) differential shaft. Check distance A from case edge to differential side gear, e.g. A = 5.40 mm (0.212´´). |  |

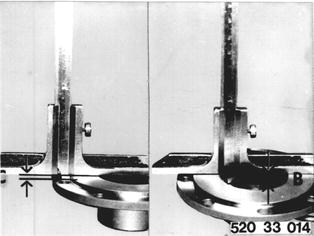

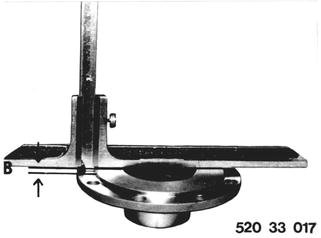

Measure distance B on cover, inside, e.g. .............................8.50 mm (0.335´´) Measure distance C on cover, outside, e.g. .........................- 2.90 mm (0.114´´) _____________________________________ Sum of B - C = D.....................5.60 mm (0.221´´) Sum of D + A .........................5.40 mm (0.212´´) _____________________________________ E = .......................................11.00 mm (0.433``) |  |

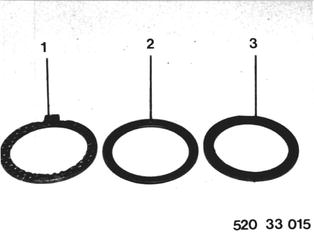

Take half of distance E (11.00 mm (0.433´´). Install thrust washers having thickness of 5.50 mm (0.216´´) less 0.10 mm (0.004´´) on each side (0.10 mm/0.004´´ is required to prevent pressing diaphragm springs flat). Thrust washers (stepped washers) are available in steps of 0.05 mm (0.002´´). Example: 1 Thrust (stepped) washer... 2.20 mm (0.087´´) 2 Diaphragm spring ............. 1.10 mm (0.043´´) 3 Thrust washer .................. 2.10 mm (0.082´´) ____________________________________ Each side............................. 5.40 mm (0.212´´) |  |

Install following parts in case one after the other. Spacer (4), outer plate (6), inner plate (7), pressure ring (8), differential side gears (9), differential gears (10) and differential shafts (11). Measure distance A from case edge to outer plate, e.g. A = 8.20 mm (0.323´´). |  |

Measure distance B on cover, e.g. B = 2.90 mm (0.114´´). |  |

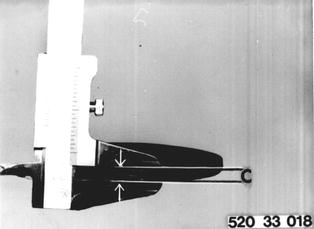

Install both diaphragm springs with their concave sides facing same direction. Measure distance C on diaphragm springs, e.g. C = 5.0 mm (0.197´´). |  |

An installed clearance of 0.1 to 0.4 mm (0.004 to 0.016´´) is required to prevent pressing diaphragm springs flat. Example: B (cover) .......................2.9 mm (0.114´´) C (diaphragm springs)...+5.0 mm (0.197´´) ________________________________ .......................................7.9 mm (0.311´´) A (case) .........................8.2 mm (0.323´´) B + C ............................-7.9 mm (0.311´´) ________________________________ D installed clearance ....0.3 mm (0.012´´) Deviations from installed clearance D can be corrected with outer plates (1) of proper thickness. |  |

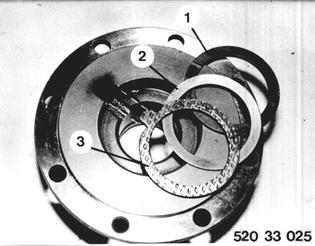

Remove all parts from housing. Installation: Install thrust washer (1) with its oil pocket facing up. Concave side of diaphragm spring (2) faces differential shaft. Smooth side of thrust (stepped) washer (3) faces diaphragm spring and tab is in opening. |  |

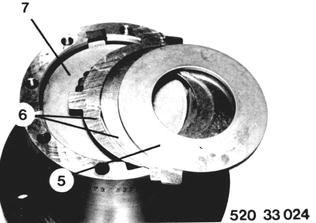

Install spacer (4), diaphragm spring (5) WITH concave side facing differential shaft, outer plate (6) and inner plate (7). Important: Outer plates determine the slip torque. Use outer plate (6) in thickness of 1.9, 2.0 or 2.1 mm (0.075, 0.079 or 0.083´´). |  |

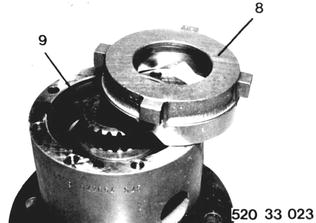

Install pressure ring (8). Turn differential side gear (9) to have it engage in spline of inner plate. |  |

Install differential gears (10) with differential shafts (11). |  |

Install differential side gear (9) and pressure ring (8). |  |

Install inner plate (7), outer plates (6) with the thinner outer plate first and diaphragm spring (5) with its concave side facing differential shaft. |  |

Install thrust washer (1) with its oil pockets and diaphragm spring (2) with its concave side facing differential shaft. Install thrust (stepped) washer (3) with its smooth side facing diaphragm spring and lubricate with grease. Install cover and tighten bolts uniformly. |  |

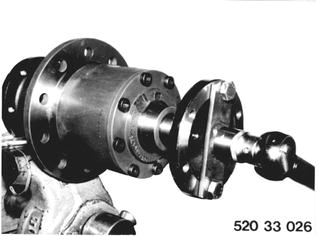

Check slip torque¹) while holding one differential side gear and turning the other. Make up tool for this purpose locally.  ¹) See Specifications ¹) See Specifications

|  |

BMW 628csi - M635csi (M6)»33 - Rear axle»33 14 613 - Limited slip differential - disassembling and assembling