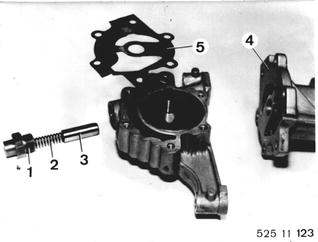

OVERHAULING OIL PUMP - Oil Pump Removed - Unscrew connector (1). Remove spring (2) and piston (3). Important: Never change relaxed spring length - see note¹). Remove oil pump cover (4). Take off connecting plate (5). Connecting plate (5) can be service installed.  ¹) See Specifications ¹) See Specifications

|  |

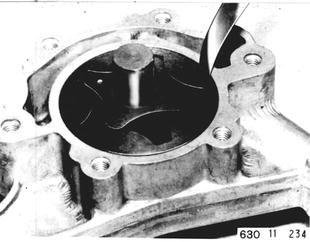

Check play¹) between outer rotor and pump body. If play exceeds specifications, replace pump body.  ¹) See Specifications ¹) See Specifications

|  |

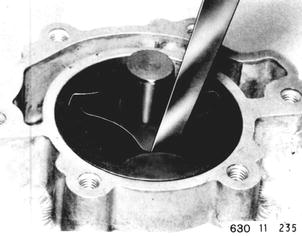

Check gap¹) between inner and outer rotors. If gap exceeds specifications, replace inner and outer rotors.  ¹9 See Specifications ¹9 See Specifications

|  |

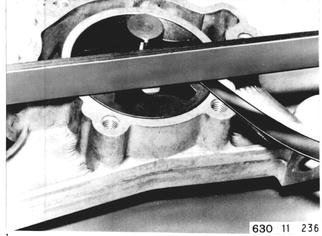

Check play¹9 between rotóe sealing surface and pump body. If play exceeds specifications, replace pump body.  ¹) See Specifications ¹) See Specifications

|  |

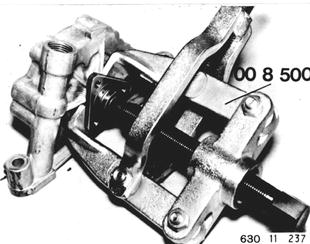

Pull off (don´t press off) output flange with Special Tool 00 8 500 from Kukko. |  |

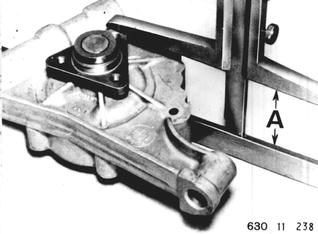

Installation: Note flange distance to inner rotor: A = 44.3 ± 0.1 mm (1.744 ± 0.004´´). |  |

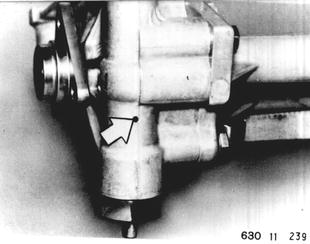

Important: Clean vent bore thoroughly. If oil pump does not have an oil bore, this bore can be drilled subsequently. |  |

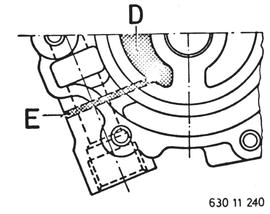

Venting of pressure chamber (D) at the beginning of delivery is accomplished by way of bore (E) and is regulated by the pressure relief piston. This will reduce the time for which the oil pressure indicator lamp is on considerably. |  |