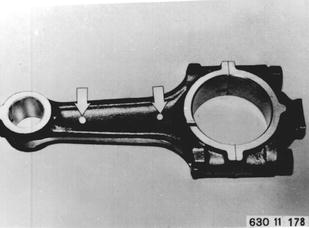

REPLACING ONE CONNECTING ROD - Piston Removed - Important: Only install connecting rods of same weight class with a total tolerance of ± 4 grams (without bearing shells) in one engine. A color code indicates the weight class. If this color code can´t be found, remove and weight another connecting rod for comparison of weight. Important: Connecting rods must not be machined. |  |

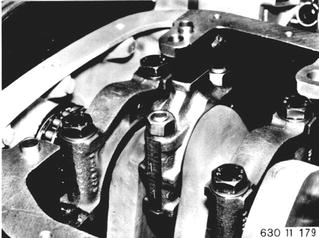

Installation: Check conrod bearing play. Place Type PG 1 Plastigage on crankshaft bearing journal dried of oil. Use old conrod bolts to measure play. Tighten connecting rods. Both cylinder reference numbers (1) must be on same side. Oil bore in conrod end faces timing chain. |  |

Tighten bearing caps to specified torque¹). Important: Don´t turn connecting rod or crankshaft. Take off bearing caps. Read bearing play¹) by width of flattened Plastigage with scale supplied. Use new conrod bolts for final installation. Narrow collar of nuts faces bearing cap.  ¹) See Specifications ¹) See Specifications

|  |